Page 112 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 112

90 Biomass Gasification, Pyrolysis and Torrefaction

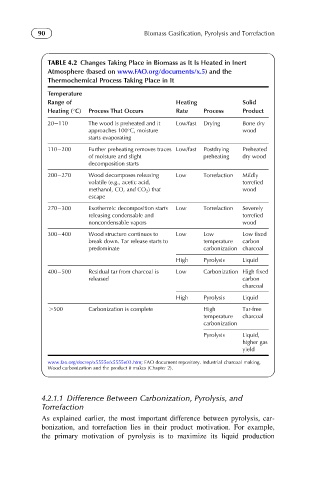

TABLE 4.2 Changes Taking Place in Biomass as It Is Heated in Inert

Atmosphere (based on www.FAO.org/documents/x.5) and the

Thermochemical Process Taking Place in It

Temperature

Range of Heating Solid

Heating ( C) Process That Occurs Rate Process Product

20 110 The wood is preheated and it Low/fast Drying Bone dry

approaches 100 C, moisture wood

starts evaporating

110 200 Further preheating removes traces Low/fast Postdrying Preheated

of moisture and slight preheating dry wood

decomposition starts

200 270 Wood decomposes releasing Low Torrefaction Mildly

volatile (e.g., acetic acid, torrefied

methanol, CO, and CO 2 ) that wood

escape

270 300 Exothermic decomposition starts Low Torrefaction Severely

releasing condensable and torrefied

noncondensable vapors wood

300 400 Wood structure continues to Low Low Low fixed

break down. Tar release starts to temperature carbon

predominate carbonization charcoal

High Pyrolysis Liquid

400 500 Residual tar from charcoal is Low Carbonization High fixed

released carbon

charcoal

High Pyrolysis Liquid

.500 Carbonization is complete High Tar-free

temperature charcoal

carbonization

Pyrolysis Liquid,

higher gas

yield

www.fao.org/docrep/x5555e/x5555e03.htm; FAO document repository. Industrial charcoal making,

Wood carbonization and the product it makes (Chapter 2).

4.2.1.1 Difference Between Carbonization, Pyrolysis, and

Torrefaction

As explained earlier, the most important difference between pyrolysis, car-

bonization, and torrefaction lies in their product motivation. For example,

the primary motivation of pyrolysis is to maximize its liquid production