Page 122 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 122

100 Biomass Gasification, Pyrolysis and Torrefaction

The basic polymeric constituents of biomass, namely hemicellulose, cel-

lulose, and lignin, are believed to react independently, and as such they do

not show the synergetic effect (Chen and Kuo, 2011). Thus, mass loss of

individual components can be simply added to get the total mass loss during

torrefaction as shown in Figure 4.5B.

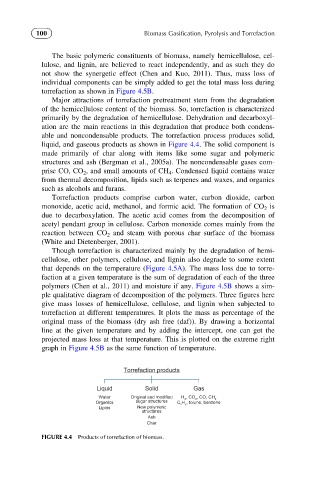

Major attractions of torrefaction pretreatment stem from the degradation

of the hemicellulose content of the biomass. So, torrefaction is characterized

primarily by the degradation of hemicellulose. Dehydration and decarboxyl-

ation are the main reactions in this degradation that produce both condens-

able and noncondensable products. The torrefaction process produces solid,

liquid, and gaseous products as shown in Figure 4.4. The solid component is

made primarily of char along with items like some sugar and polymeric

structures and ash (Bergman et al., 2005a). The noncondensable gases com-

prise CO, CO 2 , and small amounts of CH 4 . Condensed liquid contains water

from thermal decomposition, lipids such as terpenes and waxes, and organics

such as alcohols and furans.

Torrefaction products comprise carbon water, carbon dioxide, carbon

monoxide, acetic acid, methanol, and formic acid. The formation of CO 2 is

due to decarboxylation. The acetic acid comes from the decomposition of

acetyl pendant group in cellulose. Carbon monoxide comes mainly from the

reaction between CO 2 and steam with porous char surface of the biomass

(White and Dietenberger, 2001).

Though torrefaction is characterized mainly by the degradation of hemi-

cellulose, other polymers, cellulose, and lignin also degrade to some extent

that depends on the temperature (Figure 4.5A). The mass loss due to torre-

faction at a given temperature is the sum of degradation of each of the three

polymers (Chen et al., 2011) and moisture if any. Figure 4.5B shows a sim-

ple qualitative diagram of decomposition of the polymers. Three figures here

give mass losses of hemicellulose, cellulose, and lignin when subjected to

torrefaction at different temperatures. It plots the mass as percentage of the

original mass of the biomass (dry ash free (daf)). By drawing a horizontal

line at the given temperature and by adding the intercept, one can get the

projected mass loss at that temperature. This is plotted on the extreme right

graph in Figure 4.5B as the same function of temperature.

Torrefaction products

Liquid Solid Gas

Water Original and modified H , CO , CO, CH 4

2

2

Organics sugar structures C x H y , tolune, benzene

Lipids New polymeric

structures

Ash

Char

FIGURE 4.4 Products of torrefaction of biomass.