Page 180 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 180

Chapter | 5 Pyrolysis 157

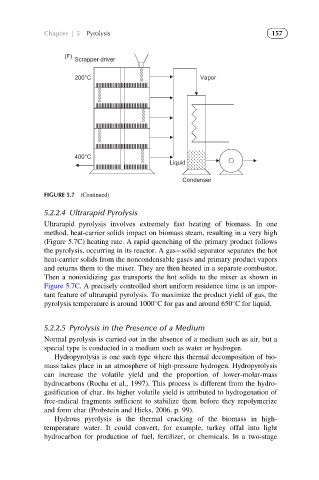

(F)

Scrapper driver

200°C Vapor

400°C

Liquid

Condenser

FIGURE 5.7 (Continued)

5.2.2.4 Ultrarapid Pyrolysis

Ultrarapid pyrolysis involves extremely fast heating of biomass. In one

method, heat-carrier solids impact on biomass steam, resulting in a very high

(Figure 5.7C) heating rate. A rapid quenching of the primary product follows

the pyrolysis, occurring in its reactor. A gas solid separator separates the hot

heat-carrier solids from the noncondensable gases and primary product vapors

and returns them to the mixer. They are then heated in a separate combustor.

Then a nonoxidizing gas transports the hot solids to the mixer as shown in

Figure 5.7C. A precisely controlled short uniform residence time is an impor-

tant feature of ultrarapid pyrolysis. To maximize the product yield of gas, the

pyrolysis temperature is around 1000 C for gas and around 650 C for liquid.

5.2.2.5 Pyrolysis in the Presence of a Medium

Normal pyrolysis is carried out in the absence of a medium such as air, but a

special type is conducted in a medium such as water or hydrogen.

Hydropyrolysis is one such type where this thermal decomposition of bio-

mass takes place in an atmosphere of high-pressure hydrogen. Hydropyrolysis

can increase the volatile yield and the proportion of lower-molar-mass

hydrocarbons (Rocha et al., 1997). This process is different from the hydro-

gasification of char. Its higher volatile yield is attributed to hydrogenation of

free-radical fragments sufficient to stabilize them before they repolymerize

and form char (Probstein and Hicks, 2006, p. 99).

Hydrous pyrolysis is the thermal cracking of the biomass in high-

temperature water. It could convert, for example, turkey offal into light

hydrocarbon for production of fuel, fertilizer, or chemicals. In a two-stage