Page 207 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 207

184 Biomass Gasification, Pyrolysis and Torrefaction

Postgasification

Product gas cleaning

+ tar

Biomass Gasifier tar + dust Clean gas

scrubbing

catalytic tar

(A) reduction

Gasifying

agent

Tar-free

Gasifier product gas

Biomass

with in situ Dust cleaning Clean gas

tar removal

(B)

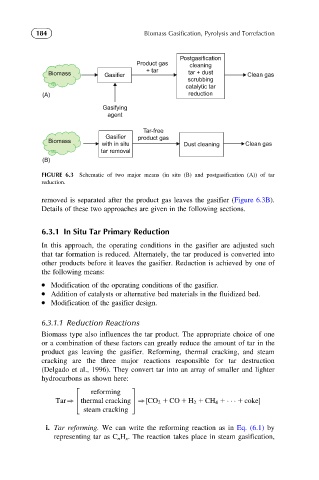

FIGURE 6.3 Schematic of two major means (in situ (B) and postgasification (A)) of tar

reduction.

removed is separated after the product gas leaves the gasifier (Figure 6.3B).

Details of these two approaches are given in the following sections.

6.3.1 In Situ Tar Primary Reduction

In this approach, the operating conditions in the gasifier are adjusted such

that tar formation is reduced. Alternately, the tar produced is converted into

other products before it leaves the gasifier. Reduction is achieved by one of

the following means:

Modification of the operating conditions of the gasifier.

Addition of catalysts or alternative bed materials in the fluidized bed.

Modification of the gasifier design.

6.3.1.1 Reduction Reactions

Biomass type also influences the tar product. The appropriate choice of one

or a combination of these factors can greatly reduce the amount of tar in the

product gas leaving the gasifier. Reforming, thermal cracking, and steam

cracking are the three major reactions responsible for tar destruction

(Delgado et al., 1996). They convert tar into an array of smaller and lighter

hydrocarbons as shown here:

2 3

reforming

Tar. thermal cracking .½CO 2 1 CO 1 H 2 1 CH 4 1 1 coke

5

4

steam cracking

i. Tar reforming. We can write the reforming reaction as in Eq. (6.1) by

representing tar as C n H x . The reaction takes place in steam gasification,