Page 58 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 58

Chapter | 2 Economic Issues of Biomass Energy Conversion 37

10 9 8

10

Capital cost, $US (1994) 10 7 6 Pressurized

Atmospheric

pressure

systems

10

systems

10 5

10 4

0.1 1 10 100

Feed input, daf t/h

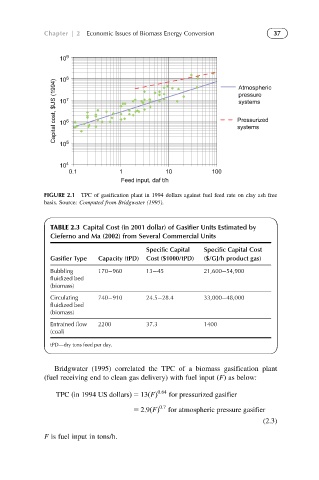

FIGURE 2.1 TPC of gasification plant in 1994 dollars against fuel feed rate on clay ash free

basis. Source: Computed from Bridgwater (1995).

TABLE 2.3 Capital Cost (in 2001 dollar) of Gasifier Units Estimated by

Cieferno and Ma (2002) from Several Commercial Units

Specific Capital Specific Capital Cost

Gasifier Type Capacity (tPD) Cost ($1000/tPD) ($/GJ/h product gas)

Bubbling 170 960 13 45 21,600 54,900

fluidized bed

(biomass)

Circulating 740 910 24.5 28.4 33,000 48,000

fluidized bed

(biomass)

Entrained flow 2200 37.3 1400

(coal)

tPD—dry tons feed per day.

Bridgwater (1995) correlated the TPC of a biomass gasification plant

(fuel receiving end to clean gas delivery) with fuel input (F) as below:

0:64

TPC ðin 1994 US dollarsÞ 5 13ðFÞ for pressurized gasifier

0:7

5 2:9ðFÞ for atmospheric pressure gasifier

(2.3)

F is fuel input in tons/h.