Page 352 - Biomedical Engineering and Design Handbook Volume 1, Fundamentals

P. 352

BIOPOLYMERS 329

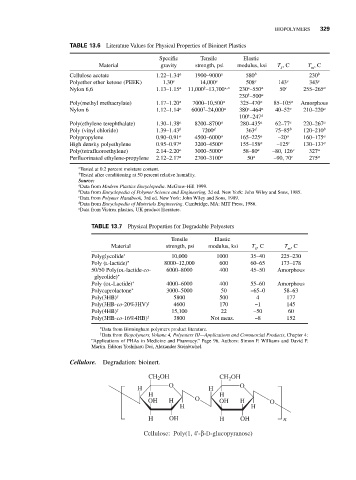

TABLE 13.6 Literature Values for Physical Properties of Bioinert Plastics

Specific Tensile Elastic

Material gravity strength, psi modulus, ksi T g , C T , C

m

Cellulose acetate 1.22–1.34 a 1900–9000 a 580 b 230 b

Polyether ether ketone (PEEK) 1.30 e 14,000 e 508 e 143 e 343 e

∗

†

Nylon 6,6 1.13–1.15 a 11,000 –13,700 ∗,a 230 –550 a 50 c 255–265 a

†

230 –500 a

Poly(methyl methacrylate) 1.17–1.20 a 7000–10,500 a 325–470 a 85–105 a Amorphous

†

Nylon 6 1.12–1.14 a 6000 –24,000 a 380 –464 a 40–52 c 210–220 a

∗

†

100 –247 a

Poly(ethylene terephthalate) 1.30–1.38 a 8200–8700 a 280–435 a 62–77 c 220–267 a

Poly (vinyl chloride) 1.39–1.43 b 7200 d 363 d 75–85 b 120–210 b

Polypropylene 0.90–0.91 a 4500–6000 a 165–225 a –20 a 160–175 a

High density polyethylene 0.95–0.97 a 3200–4500 a 155–158 a –125 c 130–137 a

Poly(tetrafluoroethylene) 2.14–2.20 a 3000–5000 a 58–80 a –80, 126 c 327 a

Perfluorinated ethylene-propylene 2.12–2.17 a 2700–3100 a 50 a –90, 70 c 275 a

∗ Tested at 0.2 percent moisture content.

† Tested after conditioning at 50 percent relative humidity.

Source:

a Data from Modern Plastics Encyclopedia. McGraw-Hill 1999.

b Data from Encyclopedia of Polymer Science and Engineering, 2d ed. New York: John Wiley and Sons, 1985.

c Data from Polymer Handbook, 3rd ed. New York: John Wiley and Sons, 1989.

d Data from Encyclopedia of Materials Engineering. Cambridge, MA: MIT Press, 1986.

e Data from Victrex plastics, UK product literature.

TABLE 13.7 Physical Properties for Degradable Polyesters

Tensile Elastic

Material strength, psi modulus, ksi T g , C T , C

m

Polyglycolide ∗ 10,000 1000 35–40 225–230

Poly (L-lactide) ∗ 8000–12,000 600 60–65 173–178

50/50 Poly(DL-lactide-co- 6000–8000 400 45–50 Amorphous

glycolide) ∗

Poly (DL-Lactide) ∗ 4000–6000 400 55–60 Amorphous

Polycaprolactone ∗ 3000–5000 50 −65–0 58–63

Poly(3HB) † 5800 500 4 177

Poly(3HB-co-20%3HV) † 4600 170 −1 145

Poly(4HB) † 15,100 22 −50 60

Poly(3HB-co-16%4HB) † 3800 Not meas. −8 152

∗

Data from Birmingham polymers product literature.

†

Data from Biopolymers, Volume 4, Polyesters III—Applications and Commercial Products, Chapter 4:

“Applications of PHAs in Medicine and Pharmacy.” Page 96. Authors: Simon F. Williams and David P.

Martin. Editors Yoshiharu Doi, Alexander Steinbuchel.

Cellulose. Degradation: bioinert.

OH

CH 2 CH 2 OH

H O H O

H H

OH H O OH H O

H H

H OH H OH n

Cellulose: Poly(1, 4'-β-D-glucopyranose)