Page 363 - Biomedical Engineering and Design Handbook Volume 1, Fundamentals

P. 363

340 BIOMATERIALS

Composite materials have a bulk phase, which is continuous, called the matrix, and one or more

dispersed, noncontinuous phases, called the reinforcement, which usually has superior mechanical or

thermal properties to the matrix. The region between the two can be simply a surface, called an inter-

face, or a third phase, called an interphase. An example of the latter is a layer of coupling agent coated

on glass fibers that facilitates adhesion of the glass to the matrix polymer.

The essence of the concept of composites is this: the bulk phase accepts the load over a large

surface area and transfers it to the reinforcement phase, which, being different, changes the mechanical

properties of the composite suitably, whether it is strength, stiffness, toughness, or fatigue resistance.

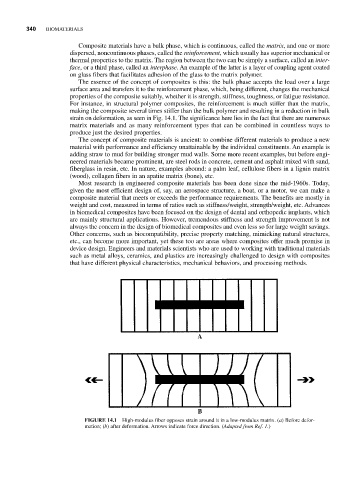

For instance, in structural polymer composites, the reinforcement is much stiffer than the matrix,

making the composite several times stiffer than the bulk polymer and resulting in a reduction in bulk

strain on deformation, as seen in Fig. 14.1. The significance here lies in the fact that there are numerous

matrix materials and as many reinforcement types that can be combined in countless ways to

produce just the desired properties.

The concept of composite materials is ancient: to combine different materials to produce a new

material with performance and efficiency unattainable by the individual constituents. An example is

adding straw to mud for building stronger mud walls. Some more recent examples, but before engi-

neered materials became prominent, are steel rods in concrete, cement and asphalt mixed with sand,

fiberglass in resin, etc. In nature, examples abound: a palm leaf, cellulose fibers in a lignin matrix

(wood), collagen fibers in an apatite matrix (bone), etc.

Most research in engineered composite materials has been done since the mid-1960s. Today,

given the most efficient design of, say, an aerospace structure, a boat, or a motor, we can make a

composite material that meets or exceeds the performance requirements. The benefits are mostly in

weight and cost, measured in terms of ratios such as stiffness/weight, strength/weight, etc. Advances

in biomedical composites have been focused on the design of dental and orthopedic implants, which

are mainly structural applications. However, tremendous stiffness and strength improvement is not

always the concern in the design of biomedical composites and even less so for large weight savings.

Other concerns, such as biocompatibility, precise property matching, mimicking natural structures,

etc., can become more important, yet these too are areas where composites offer much promise in

device design. Engineers and materials scientists who are used to working with traditional materials

such as metal alloys, ceramics, and plastics are increasingly challenged to design with composites

that have different physical characteristics, mechanical behaviors, and processing methods.

FIGURE 14.1 High-modulus fiber opposes strain around it in a low-modulus matrix. (a) Before defor-

mation; (b) after deformation. Arrows indicate force direction. (Adapted from Ref. 1.)