Page 103 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 103

82 MEDICAL DEVICE DESIGN

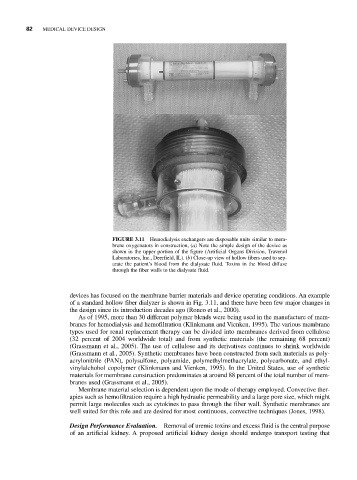

FIGURE 3.11 Hemodialysis exchangers are disposable units similar to mem-

brane oxygenators in construction, (a) Note the simple design of the device as

shown in the upper portion of the figure (Artificial Organs Division, Travenol

Laboratories, Inc., Deerfield, IL). (b) Close-up view of hollow fibers used to sep-

arate the patient’s blood from the dialysate fluid. Toxins in the blood diffuse

through the fiber walls to the dialysate fluid.

devices has focused on the membrane barrier materials and device operating conditions. An example

of a standard hollow fiber dialyzer is shown in Fig. 3.11, and there have been few major changes in

the design since its introduction decades ago (Ronco et al., 2000).

As of 1995, more than 30 different polymer blends were being used in the manufacture of mem-

branes for hemodialysis and hemofiltration (Klinkmann and Vienken, 1995). The various membrane

types used for renal replacement therapy can be divided into membranes derived from cellulose

(32 percent of 2004 worldwide total) and from synthetic materials (the remaining 68 percent)

(Grassmann et al., 2005). The use of cellulose and its derivatives continues to shrink worldwide

(Grassmann et al., 2005). Synthetic membranes have been constructed from such materials as poly-

acrylonitrile (PAN), polysulfone, polyamide, polymethylmethacrylate, polycarbonate, and ethyl-

vinylalchohol copolymer (Klinkmann and Vienken, 1995). In the United States, use of synthetic

materials for membrane construction predominates at around 88 percent of the total number of mem-

branes used (Grassmann et al., 2005).

Membrane material selection is dependent upon the mode of therapy employed. Convective ther-

apies such as hemofiltration require a high hydraulic permeability and a large pore size, which might

permit large molecules such as cytokines to pass through the fiber wall. Synthetic membranes are

well suited for this role and are desired for most continuous, convective techniques (Jones, 1998).

Design Performance Evaluation. Removal of uremic toxins and excess fluid is the central purpose

of an artificial kidney. A proposed artificial kidney design should undergo transport testing that