Page 481 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 481

APPLIED UNIVERSAL DESIGN 459

16.2.4 Reality Check

Commitment to a design refers to the point at which you have invested too many resources to make

substantial revisions. At this point, your options may be to continue with your current design or scrap

it entirely. Best practice suggests that you keep your design on paper (or computer) as long as pos-

7

sible before investing funds on the product’s manufacture. As part of good design practice, before

you are committed to a design, do a reality check. This is where you ensure that the features that you

have selected to satisfy your customers are appropriate. Simply selecting to meet the requirements

calculated to be of greatest importance as a result of a focus group may lead to a design that no one

wants. For example, you might miss the features that are commonplace and therefore expected. This

may result from a focus group’s failure to list important features because they assume that all prod-

ucts will have them. Examples include a remote control for a television, the automatic shutoff of a

coffee pot, the ability to fold a manual wheelchair, and the light weight of a walker. When designing

products for a broad population, the statistics from the quality function deployment, if improperly

interpreted, may lead to the production of a two-door minivan with seven sporty bucket seats that

cannot accommodate infant seats. However, when applied correctly, techniques such as quality func-

tion deployment will aid the design team in fully understanding the customers’ needs and wants. It

is one of many important tools that will lead to a successful, safe, and cost-effective design.

16.2.5 Quality Function Deployment

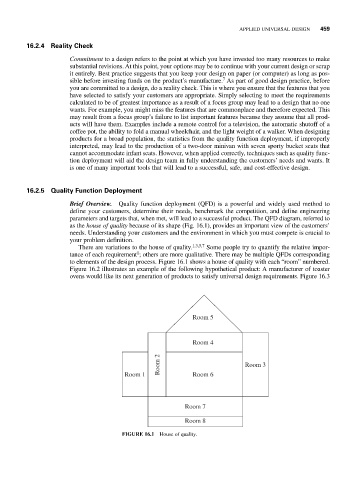

Brief Overview. Quality function deployment (QFD) is a powerful and widely used method to

define your customers, determine their needs, benchmark the competition, and define engineering

parameters and targets that, when met, will lead to a successful product. The QFD diagram, referred to

as the house of quality because of its shape (Fig. 16.1), provides an important view of the customers’

needs. Understanding your customers and the environment in which you must compete is crucial to

your problem definition.

There are variations to the house of quality. 1,3,5,7 Some people try to quantify the relative impor-

1

tance of each requirement ; others are more qualitative. There may be multiple QFDs corresponding

to elements of the design process. Figure 16.1 shows a house of quality with each “room” numbered.

Figure 16.2 illustrates an example of the following hypothetical product: A manufacturer of toaster

ovens would like its next generation of products to satisfy universal design requirements. Figure 16.3

Room 5

Room 4

Room 2 Room 3

Room 1 Room 6

Room 7

Room 8

FIGURE 16.1 House of quality.