Page 105 - Biorefinery 2030

P. 105

2 Different Aspects of Industrial Symbiosis at the Bazancourt-Pomacle Biorefinery 73

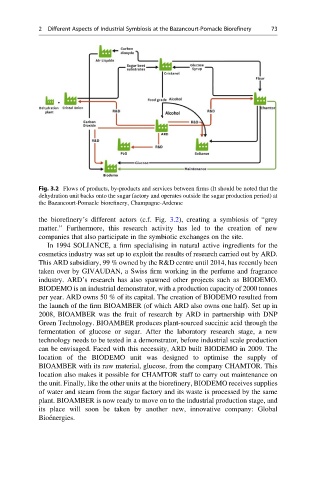

Fig. 3.2 Flows of products, by-products and services between firms (It should be noted that the

dehydration unit backs onto the sugar factory and operates outside the sugar production period) at

the Bazancourt-Pomacle biorefinery, Champagne-Ardenne

the biorefinery’s different actors (c.f. Fig. 3.2), creating a symbiosis of “grey

matter.” Furthermore, this research activity has led to the creation of new

companies that also participate in the symbiotic exchanges on the site.

In 1994 SOLIANCE, a firm specialising in natural active ingredients for the

cosmetics industry was set up to exploit the results of research carried out by ARD.

This ARD subsidiary, 99 % owned by the R&D centre until 2014, has recently been

taken over by GIVAUDAN, a Swiss firm working in the perfume and fragrance

industry. ARD’s research has also spawned other projects such as BIODEMO.

BIODEMO is an industrial demonstrator, with a production capacity of 2000 tonnes

per year. ARD owns 50 % of its capital. The creation of BIODEMO resulted from

the launch of the firm BIOAMBER (of which ARD also owns one half). Set up in

2008, BIOAMBER was the fruit of research by ARD in partnership with DNP

Green Technology. BIOAMBER produces plant-sourced succinic acid through the

fermentation of glucose or sugar. After the laboratory research stage, a new

technology needs to be tested in a demonstrator, before industrial scale production

can be envisaged. Faced with this necessity, ARD built BIODEMO in 2009. The

location of the BIODEMO unit was designed to optimise the supply of

BIOAMBER with its raw material, glucose, from the company CHAMTOR. This

location also makes it possible for CHAMTOR staff to carry out maintenance on

the unit. Finally, like the other units at the biorefinery, BIODEMO receives supplies

of water and steam from the sugar factory and its waste is processed by the same

plant. BIOAMBER is now ready to move on to the industrial production stage, and

its place will soon be taken by another new, innovative company: Global

Bioe ´nergies.