Page 179 - Biosystems Engineering

P. 179

158 Cha pte r F o u r

Water moves to the zones with the lowest temperatures, which

helps reduce the temperature differences in the root zone. With the

increase in the depth of installation of the heating cable, the amount

of water flowing toward the root zone decreased considerably. Such

a decrease is enhanced by the increase in heating-cable spacing.

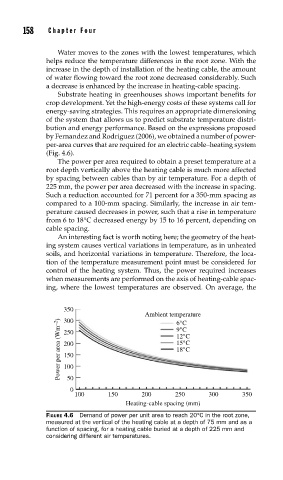

Substrate heating in greenhouses shows important benefits for

crop development. Yet the high-energy costs of these systems call for

energy-saving strategies. This requires an appropriate dimensioning

of the system that allows us to predict substrate temperature distri-

bution and energy performance. Based on the expressions proposed

by Fernandez and Rodriguez (2006), we obtained a number of power-

per-area curves that are required for an electric cable–heating system

(Fig. 4.6).

The power per area required to obtain a preset temperature at a

root depth vertically above the heating cable is much more affected

by spacing between cables than by air temperature. For a depth of

225 mm, the power per area decreased with the increase in spacing.

Such a reduction accounted for 71 percent for a 350-mm spacing as

compared to a 100-mm spacing. Similarly, the increase in air tem-

perature caused decreases in power, such that a rise in temperature

from 6 to 18°C decreased energy by 15 to 16 percent, depending on

cable spacing.

An interesting fact is worth noting here; the geometry of the heat-

ing system causes vertical variations in temperature, as in unheated

soils, and horizontal variations in temperature. Therefore, the loca-

tion of the temperature measurement point must be considered for

control of the heating system. Thus, the power required increases

when measurements are performed on the axis of heating-cable spac-

ing, where the lowest temperatures are observed. On average, the

350

Ambient temperature

Power per area (Wm –2 ) 250 12°C

300

6°C

9°C

15°C

200

18°C

150

100

50

0

100 150 200 250 300 350

Heating-cable spacing (mm)

FIGURE 4.6 Demand of power per unit area to reach 20°C in the root zone,

measured at the vertical of the heating cable at a depth of 75 mm and as a

function of spacing, for a heating cable buried at a depth of 225 mm and

considering different air temperatures.