Page 247 - Biosystems Engineering

P. 247

Biomass Pyr olysis and Bio-Oil Refineries 225

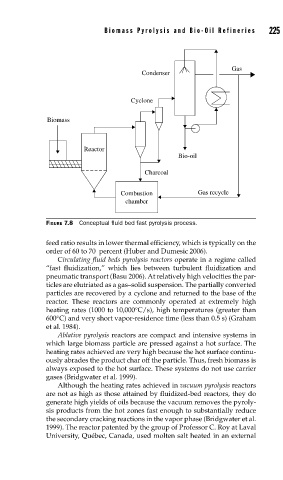

Gas

Condenser

Cyclone

Biomass

Reactor

Bio-oil

Charcoal

Combustion Gas recycle

chamber

FIGURE 7.8 Conceptual fl uid bed fast pyrolysis process.

feed ratio results in lower thermal efficiency, which is typically on the

order of 60 to 70 percent (Huber and Dumesic 2006).

Circulating fluid beds pyrolysis reactors operate in a regime called

“fast fluidization,” which lies between turbulent fluidization and

pneumatic transport (Basu 2006). At relatively high velocities the par-

ticles are elutriated as a gas–solid suspension. The partially converted

particles are recovered by a cyclone and returned to the base of the

reactor. These reactors are commonly operated at extremely high

heating rates (1000 to 10,000°C/s), high temperatures (greater than

600°C) and very short vapor-residence time (less than 0.5 s) (Graham

et al. 1984).

Ablative pyrolysis reactors are compact and intensive systems in

which large biomass particle are pressed against a hot surface. The

heating rates achieved are very high because the hot surface continu-

ously abrades the product char off the particle. Thus, fresh biomass is

always exposed to the hot surface. These systems do not use carrier

gases (Bridgwater et al. 1999).

Although the heating rates achieved in vacuum pyrolysis reactors

are not as high as those attained by fluidized-bed reactors, they do

generate high yields of oils because the vacuum removes the pyroly-

sis products from the hot zones fast enough to substantially reduce

the secondary cracking reactions in the vapor phase (Bridgwater et al.

1999). The reactor patented by the group of Professor C. Roy at Laval

University, Québec, Canada, used molten salt heated in an external