Page 282 - Biosystems Engineering

P. 282

260 Cha pte r Ei g h t

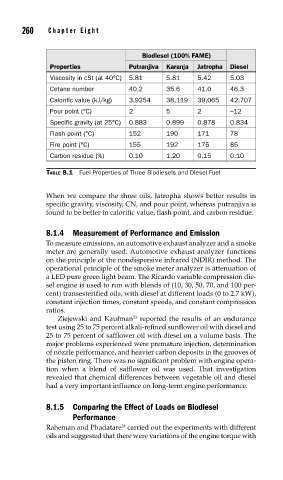

Biodiesel (100% FAME)

Properties Putranjiva Karanja Jatropha Diesel

Viscosity in cSt (at 40°C) 5.81 5.81 5.42 5.03

Cetane number 40.2 35.6 41.0 46.3

Calorific value (kJ/kg) 3,9254 38,119 39,065 42,707

Pour point (°C) 2 5 2 –12

Specific gravity (at 25°C) 0.883 0.899 0.878 0.834

Flash point (°C) 152 190 171 78

Fire point (°C) 155 192 175 85

Carbon residue (%) 0.10 1.20 0.15 0.10

TABLE 8.1 Fuel Properties of Three Biodiesels and Diesel Fuel

When we compare the three oils, Jatropha shows better results in

specific gravity, viscosity, CN, and pour point, whereas putranjiva is

found to be better in calorific value, flash point, and carbon residue.

8.1.4 Measurement of Performance and Emission

To measure emissions, an automotive exhaust analyzer and a smoke

meter are generally used. Automotive exhaust analyzer functions

on the principle of the nondispersive infrared (NDIR) method. The

operational principle of the smoke meter analyzer is attenuation of

a LED pure green light beam. The Ricardo variable compression die-

sel engine is used to run with blends of (10, 30, 50, 70, and 100 per-

cent) transesterified oils, with diesel at different loads (0 to 2.7 kW),

constant injection times, constant speeds, and constant compression

ratios.

Ziejewski and Kaufman reported the results of an endurance

23

test using 25 to 75 percent alkali-refined sunflower oil with diesel and

25 to 75 percent of safflower oil with diesel on a volume basis. The

major problems experienced were premature injection, determination

of nozzle performance, and heavier carbon deposits in the grooves of

the piston ring. There was no significant problem with engine opera-

tion when a blend of safflower oil was used. That investigation

revealed that chemical differences between vegetable oil and diesel

had a very important influence on long-term engine performance.

8.1.5 Comparing the Effect of Loads on Biodiesel

Performance

24

Raheman and Phadatare carried out the experiments with different

oils and suggested that there were variations of the engine torque with