Page 283 - Biosystems Engineering

P. 283

Biodiesel and Ethanol in Engines 261

800

700 Diesel

Putranjiva oil

Karanja oil

600 Jatropha oil

BSFC (g/kWh) 500

400

300

200

0.0 0.5 1.0 1.5 2.0 2.5 3.0

Brake power (kW)

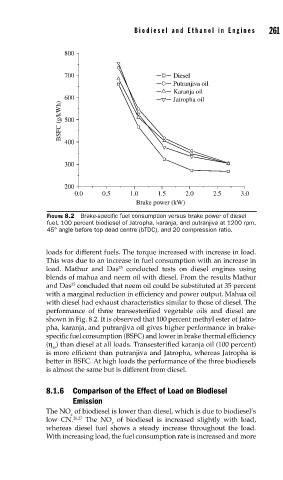

FIGURE 8.2 Brake-specifi c fuel consumption versus brake power of diesel

fuel, 100 percent biodiesel of Jatropha, karanja, and putranjiva at 1200 rpm,

45° angle before top dead centre (bTDC), and 20 compression ratio.

loads for different fuels. The torque increased with increase in load.

This was due to an increase in fuel consumption with an increase in

load. Mathur and Das conducted tests on diesel engines using

25

blends of mahua and neem oil with diesel. From the results Mathur

25

and Das concluded that neem oil could be substituted at 35 percent

with a marginal reduction in efficiency and power output. Mahua oil

with diesel had exhaust characteristics similar to those of diesel. The

performance of three transesterified vegetable oils and diesel are

shown in Fig. 8.2. It is observed that 100 percent methyl ester of Jatro-

pha, karanja, and putranjiva oil gives higher performance in brake-

specific fuel consumption (BSFC) and lower in brake thermal efficiency

(η ) than diesel at all loads. Transesterified karanja oil (100 percent)

bt

is more efficient than putranjiva and Jatropha, whereas Jatropha is

better in BSFC. At high loads the performance of the three biodiesels

is almost the same but is different from diesel.

8.1.6 Comparison of the Effect of Load on Biodiesel

Emission

The NO of biodiesel is lower than diesel, which is due to biodiesel’s

x

low CN. 26,27 The NO of biodiesel is increased slightly with load,

x

whereas diesel fuel shows a steady increase throughout the load.

With increasing load, the fuel consumption rate is increased and more