Page 394 - Biosystems Engineering

P. 394

Extraction, Refining, and Stabilization of Edible Oils 371

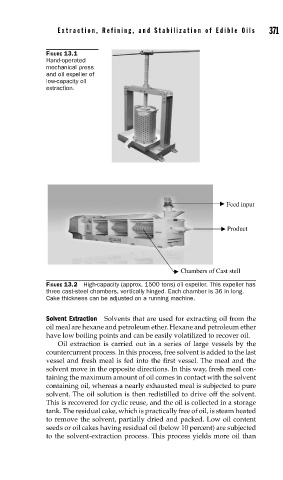

FIGURE 13.1

Hand-operated

mechanical press

and oil expeller of

low-capacity oil

extraction.

Feed input

Product

Chambers of Cast stell

FIGURE 13.2 High-capacity (approx. 1500 tons) oil expeller. This expeller has

three cast-steel chambers, vertically hinged. Each chamber is 36 in long.

Cake thickness can be adjusted on a running machine.

Solvent Extraction Solvents that are used for extracting oil from the

oil meal are hexane and petroleum ether. Hexane and petroleum ether

have low boiling points and can be easily volatilized to recover oil.

Oil extraction is carried out in a series of large vessels by the

countercurrent process. In this process, free solvent is added to the last

vessel and fresh meal is fed into the first vessel. The meal and the

solvent move in the opposite directions. In this way, fresh meal con-

taining the maximum amount of oil comes in contact with the solvent

containing oil, whereas a nearly exhausted meal is subjected to pure

solvent. The oil solution is then redistilled to drive off the solvent.

This is recovered for cyclic reuse, and the oil is collected in a storage

tank. The residual cake, which is practically free of oil, is steam heated

to remove the solvent, partially dried and packed. Low oil content

seeds or oil cakes having residual oil (below 10 percent) are subjected

to the solvent-extraction process. This process yields more oil than