Page 38 - Boiler Operator’s Handbook

P. 38

Operating Wisely 23

extracted in high pressure turbines

reduces the temperature of the steam

so much that generating any addi-

tional power with that steam would

result in the steam reaching saturated

conditions where droplets of water

would form, strike the rapidly rotat-

ing turbine blades, and damage the

turbine. So utility plants typically

have reheaters, additional tubes in

the boiler, that are exposed to the flue

gases before they reach the boiler sec-

tion. There the steam from the high

pressure turbine is heated again to

increase its superheat before continu-

ing through the intermediate pressure

turbine. The reheater is “convective”

because the superheater shields it

from the radiant heat of the furnace

and it is heated only by the flowing

flue gas. Each “stage” of a turbine has

different inlet and outlet pressures. So

the reheater operates at a lower pres-

sure than the boiler and superheater

but can have an outlet temperature as

high as the superheater.

As pressure decreases the vol-

ume of steam increases. To accom-

modate the increasing volume of the

steam the turbine casing would have

to grow in size substantially, so much

so that it would become extreme-

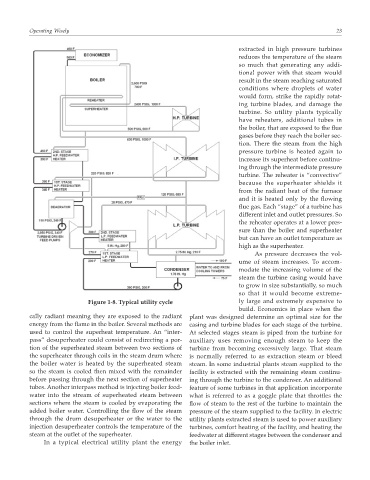

Figure 1-8. Typical utility cycle ly large and extremely expensive to

build. Economics in place when the

cally radiant meaning they are exposed to the radiant plant was designed determine an optimal size for the

energy from the flame in the boiler. Several methods are casing and turbine blades for each stage of the turbine.

used to control the superheat temperature. An “inter- At selected stages steam is piped from the turbine for

pass” desuperheater could consist of redirecting a por- auxiliary uses removing enough steam to keep the

tion of the superheated steam between two sections of turbine from becoming excessively large. That steam

the superheater through coils in the steam drum where is normally referred to as extraction steam or bleed

the boiler water is heated by the superheated steam steam. In some industrial plants steam supplied to the

so the steam is cooled then mixed with the remainder facility is extracted with the remaining steam continu-

before passing through the next section of superheater ing through the turbine to the condenser. An additional

tubes. Another interpass method is injecting boiler feed- feature of some turbines in that application incorporate

water into the stream of superheated steam between what is referred to as a goggle plate that throttles the

sections where the steam is cooled by evaporating the flow of steam to the rest of the turbine to maintain the

added boiler water. Controlling the flow of the steam pressure of the steam supplied to the facility. In electric

through the drum desuperheater or the water to the utility plants extracted steam is used to power auxiliary

injection desuperheater controls the temperature of the turbines, comfort heating of the facility, and heating the

steam at the outlet of the superheater. feedwater at different stages between the condenser and

In a typical electrical utility plant the energy the boiler inlet.