Page 256 - Boiler_Operators_Handbook,_Second_Edition

P. 256

Consumables 241

we never make mistakes, right? Now that I know a few sound indication of high degrees of hardness in the wa-

people that have been seriously injured handling treat- ter. When I asked about the regeneration of their soften-

ment chemicals I can honestly say that the wise operator ers I was told they did it just like they always did, every

uses all the protective gear. Wednesday. It didn’t seem to matter to them that the

I regularly thank God that I’m not one of those steam demand on the plant, and makeup, had tripled in

hard heads that got hurt handling chemicals, there’s the last three years. The softeners ran out of sodium ions

nothing other than will and dumb luck that prevented on Monday.

it. You may feel you look stupid in the clunky rubber Applying the chemicals in a uniform matter, con-

boots, silly rubber apron, klutzy rubber gloves and the sistent with the rate of boiler water makeup will mini-

face shield that steams up so it’s hard to see what you’re mize their use by making them most effective. Some

doing—but you’re safe. Not wearing that outfit is taking systems, such as low pressure hot water heating sys-

a chance on living with a serious injury for the rest of tems, require very little treatment because the system

your life; wear it. is closed and losses of water are very limited so shot

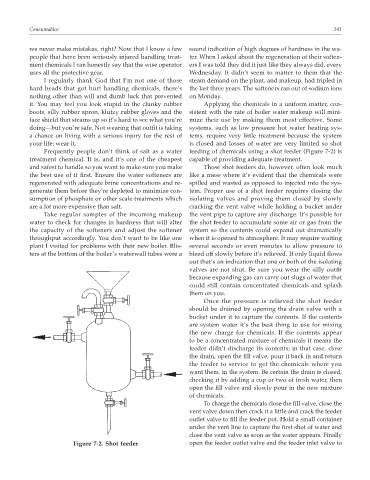

Frequently people don’t think of salt as a water feeding of chemicals using a shot feeder (Figure 7-2) is

treatment chemical. It is, and it’s one of the cheapest capable of providing adequate treatment.

and safest to handle so you want to make sure you make Those shot feeders do, however, often look much

the best use of it first. Ensure the water softeners are like a mess where it’s evident that the chemicals were

regenerated with adequate brine concentrations and re- spilled and wasted as opposed to injected into the sys-

generate them before they’re depleted to minimize con- tem. Proper use of a shot feeder requires closing the

sumption of phosphate or other scale treatments which isolating valves and proving them closed by slowly

are a lot more expensive than salt. cracking the vent valve while holding a bucket under

Take regular samples of the incoming makeup the vent pipe to capture any discharge. It’s possible for

water to check for changes in hardness that will alter the shot feeder to accumulate some air or gas from the

the capacity of the softeners and adjust the softener system so the contents could expand out dramatically

throughput accordingly. You don’t want to be like one when it is opened to atmosphere. It may require waiting

plant I visited for problems with their new boiler. Blis- several seconds or even minutes to allow pressure to

ters at the bottom of the boiler’s waterwall tubes were a bleed off slowly before it’s relieved. If only liquid flows

out that’s an indication that one or both of the isolating

valves are not shut. Be sure you wear the silly outfit

because expanding gas can carry out slugs of water that

could still contain concentrated chemicals and splash

them on you.

Once the pressure is relieved the shot feeder

should be drained by opening the drain valve with a

bucket under it to capture the contents. If the contents

are system water it’s the best thing to use for mixing

the new charge for chemicals. If the contents appear

to be a concentrated mixture of chemicals it means the

feeder didn’t discharge its contents; in that case, close

the drain, open the fill valve, pour it back in and return

the feeder to service to get the chemicals where you

want them, in the system. Be certain the drain is closed,

checking it by adding a cup or two of fresh water, then

open the fill valve and slowly pour in the new mixture

of chemicals.

To charge the chemicals close the fill valve, close the

vent valve down then crack it a little and crack the feeder

outlet valve to fill the feeder pot. Hold a small container

under the vent line to capture the first shot of water and

close the vent valve as soon as the water appears. Finally

Figure 7-2. Shot feeder open the feeder outlet valve and the feeder inlet valve to