Page 442 - Boiler_Operators_Handbook,_Second_Edition

P. 442

Controls 427

Thermometers and temperature transmitters are

occasionally installed in such a manner that they’re use-

less. The temperature sensing portion of the instrument

must be in the process fluid where it’s flowing. One

measurement that is always a problem is boiler stack

temperature. I’ve encountered situations where the

stack thermometers had stems so short that they didn’t

penetrate the stack. On others the thermometer bulb

was located in a zone where the flue gas was idle, a stag-

nant zone where the gas was much cooler than the flow-

ing flue gas. Here’s one spot where modern technology

has created some problems because the two common

measures used for temperature detection, RTDs and

thermocouples, are point instruments, they only sense

temperature at one point.

We used to have these wonderful capillary type

temperature transmitter elements that allowed us to

stretch the probe back and forth across the stack or

boiler outlet several times in a pattern that insured we

had an average reading of the gas temperature. The

problem is they were filled with mercury. I wouldn’t

recommend an RTD for stack temperature service

because they can’t take high temperatures that can oc-

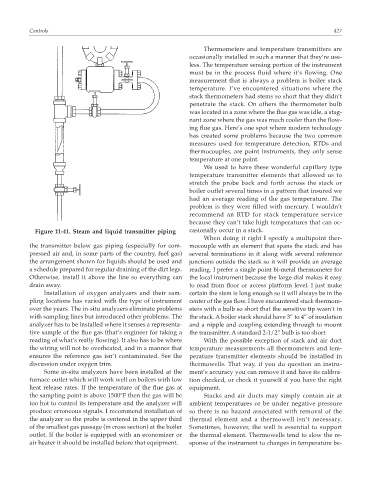

Figure 11-41. Steam and liquid transmitter piping casionally occur in a stack.

When doing it right I specify a multipoint ther-

the transmitter below gas piping (especially for com- mocouple with an element that spans the stack and has

pressed air and, in some parts of the country, fuel gas) several terminations in it along with several reference

the arrangement shown for liquids should be used and junctions outside the stack so it will provide an average

a schedule prepared for regular draining of the dirt legs. reading. I prefer a single point bi-metal thermometer for

Otherwise, install it above the line so everything can the local instrument because the large dial makes it easy

drain away. to read from floor or access platform level. I just make

Installation of oxygen analyzers and their sam- certain the stem is long enough so it will always be in the

pling locations has varied with the type of instrument center of the gas flow. I have encountered stack thermom-

over the years. The in-situ analyzers eliminate problems eters with a bulb so short that the sensitive tip wasn’t in

with sampling lines but introduced other problems. The the stack. A boiler stack should have 3” to 4” of insulation

analyzer has to be installed where it senses a representa- and a nipple and coupling extending through to mount

tive sample of the flue gas (that’s engineer for taking a the transmitter. A standard 2-1/2” bulb is too short.

reading of what’s really flowing). It also has to be where With the possible exception of stack and air duct

the wiring will not be overheated, and in a manner that temperature measurements all thermometers and tem-

ensures the reference gas isn’t contaminated. See the perature transmitter elements should be installed in

discussion under oxygen trim. thermowells. That way, if you do question an instru-

Some in-situ analyzers have been installed at the ment’s accuracy you can remove it and have its calibra-

furnace outlet which will work well on boilers with low tion checked, or check it yourself if you have the right

heat release rates. If the temperature of the flue gas at equipment.

the sampling point is above 1500°F then the gas will be Stacks and air ducts may simply contain air at

too hot to control its temperature and the analyzer will ambient temperatures or be under negative pressure

produce erroneous signals. I recommend installation of so there is no hazard associated with removal of the

the analyzer so the probe is centered in the upper third thermal element and a thermowell isn’t necessary.

of the smallest gas passage (in cross section) at the boiler Sometimes, however, the well is essential to support

outlet. If the boiler is equipped with an economizer or the thermal element. Thermowells tend to slow the re-

air heater it should be installed before that equipment. sponse of the instrument to changes in temperature be-