Page 439 - Boiler_Operators_Handbook,_Second_Edition

P. 439

424 Boiler Operator’s Handbook

get strange results when the temperature of the oil in

the tank and the oil delivered differ considerably. Some-

times it pays to take another reading on a tank a day

later to ensure the change in volume is accounted for.

One of the most valuable and important instru-

ments in any steam plant is the drum level gauge on the

boiler. It’s also one that can go wrong with disaster close

on its heels. The most important thing I can say about

that instrument is that if you don’t trust its indication,

shut the boiler down. Either leg can plug and present a

false water level indication. Keep in mind that the only

force that produces the level indication in that gauge

glass is the level in the boiler and you’re measuring

something in inches of water column.

The steam side can be plugged to the point that

only a small opening remains and the steam condenses

in the glass faster than it can get through that small open-

ing. The result is the level rises, compared to the level in

the boiler, until the condensing matches the amount that

can get through the opening. If there’s nothing but a

small opening in the water leg the level in the glass may

rise to produce the additional pressure needed to force

the condensate through the small opening. Any leak on

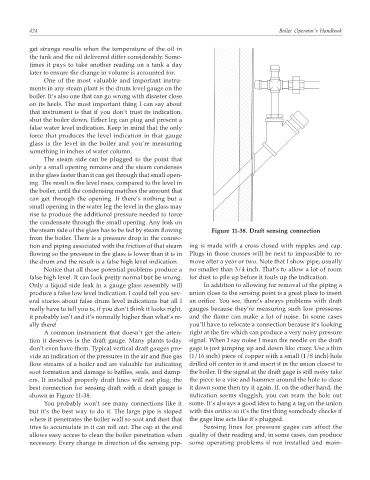

the steam side of the glass has to be fed by steam flowing Figure 11-38. Draft sensing connection

from the boiler. There is a pressure drop in the connec-

tion and piping associated with the friction of that steam ing is made with a cross closed with nipples and cap.

flowing so the pressure in the glass is lower than it is in Plugs in those crosses will be next to impossible to re-

the drum and the result is a false high level indication. move after a year or two. Note that I show pipe, usually

Notice that all those potential problems produce a no smaller than 3/4 inch. That’s to allow a lot of room

false high level. It can look pretty normal but be wrong. for dust to pile up before it fouls up the indication.

Only a liquid side leak in a gauge glass assembly will In addition to allowing for removal of the piping a

produce a false low level indication. I could tell you sev- union close to the sensing point is a great place to insert

eral stories about false drum level indications but all I an orifice. You see, there’s always problems with draft

really have to tell you is, if you don’t think it looks right, gauges because they’re measuring such low pressures

it probably isn’t and it’s normally higher than what’s re- and the flame can make a lot of noise. In some cases

ally there! you’ll have to relocate a connection because it’s looking

A common instrument that doesn’t get the atten- right at the fire which can produce a very noisy pressure

tion it deserves is the draft gauge. Many plants today signal. When I say noise I mean the needle on the draft

don’t even have them. Typical vertical draft gauges pro- gage is just jumping up and down like crazy. Use a thin

vide an indication of the pressures in the air and flue gas (1/16 inch) piece of copper with a small (1/8 inch) hole

flow streams of a boiler and are valuable for indicating drilled off center in it and insert it in the union closest to

soot formation and damage to baffles, seals, and damp- the boiler. If the signal at the draft gage is still noisy take

ers. If installed properly draft lines will not plug; the the piece to a vise and hammer around the hole to close

best connection for sensing draft with a draft gauge is it down some then try it again. If, on the other hand, the

shown in Figure 11-38. indication seems sluggish, you can ream the hole out

You probably won’t see many connections like it some. It’s always a good idea to hang a tag on the union

but it’s the best way to do it. The large pipe is sloped with this orifice so it’s the first thing somebody checks if

where it penetrates the boiler wall so soot and dust that the gage line acts like it’s plugged.

tries to accumulate in it can roll out. The cap at the end Sensing lines for pressure gages can affect the

allows easy access to clean the boiler penetration when quality of their reading and, in some cases, can produce

necessary. Every change in direction of the sensing pip- some operating problems if not installed and main-