Page 81 - Boiler plant and distribution system optimization manual

P. 81

66 Boiler Plant and Distribution System Optimization Manual

on which is in use. The volume change, percent

CO or O , can be read in percent on a convenient

2

2

scale.

FINDING STACK LOSSES

By measuring the net stack temperature

(Stack temperature—combustion air tempera-

ture), combustion tables or slide rule (Figure 7.9)

can be used to determine flue gas losses.

Measuring Flue gas Oxygen on a

Continuous Basis

There are three common methods of measur-

ing oxygen in flue gas on a continuous basis. The

paramagnetic sensor, the wet electrochemical cell

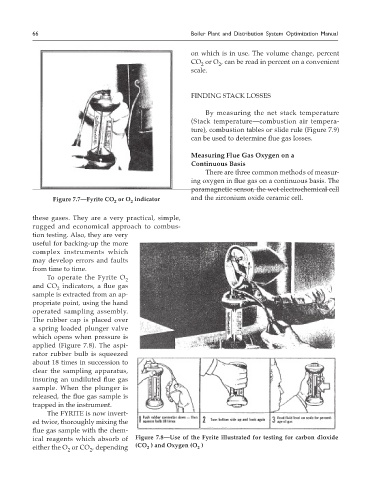

Figure 7.7—Fyrite CO or O indicator and the zirconium oxide ceramic cell.

2

2

these gases. They are a very practical, simple,

rugged and economical approach to combus-

tion testing. Also, they are very

useful for backing-up the more

complex instruments which

may develop errors and faults

from time to time.

To operate the Fyrite O

2

and CO indicators, a flue gas

2

sample is extracted from an ap-

propriate point, using the hand

operated sampling assembly.

The rubber cap is placed over

a spring loaded plunger valve

which opens when pressure is

applied (Figure 7.8). The aspi-

rator rubber bulb is squeezed

about 18 times in succession to

clear the sampling apparatus,

insuring an undiluted flue gas

sample. When the plunger is

released, the flue gas sample is

trapped in the instrument.

The FYRITE is now invert-

ed twice, thoroughly mixing the

flue gas sample with the chem-

ical reagents which absorb of Figure 7.8—Use of the Fyrite illustrated for testing for carbon dioxide

either the O or CO , depending (CO ) and Oxygen (O )

2

2

2

2