Page 65 - Build Your Own Quadcopter_ Power Up Your Designs with the Parallax Elev-8

P. 65

44 Bu il d Y o ur O w n Q u a d c o p t e r

Beginning the Build

I have now come to the point where the actual build starts. Remember to have all the

recommended tools, all the kit parts, and a well-lighted and comfortable work area available.

These steps will go a long way in making the whole build experience enjoyable.

Motor Set Screws

Start by applying Blue Loctite to the motor set screws, to prevent them from coming loose

during flight and causing equipment failure.

1. Locate the Blue Loctite 242, the four motors, and the small Allen wrench in the

Elev-8 Hardware Kit.

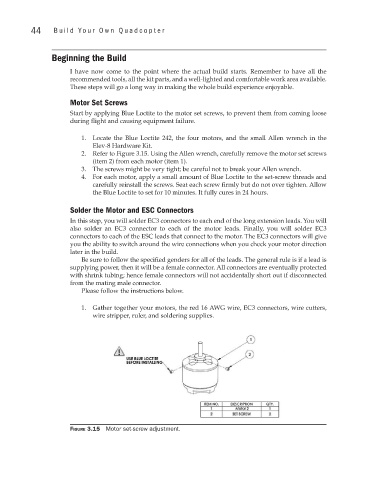

2. Refer to Figure 3.15. Using the Allen wrench, carefully remove the motor set screws

(item 2) from each motor (item 1).

3. The screws might be very tight; be careful not to break your Allen wrench.

4. For each motor, apply a small amount of Blue Loctite to the set-screw threads and

carefully reinstall the screws. Seat each screw firmly but do not over tighten. Allow

the Blue Loctite to set for 10 minutes. It fully cures in 24 hours.

Solder the Motor and ESC Connectors

In this step, you will solder EC3 connectors to each end of the long extension leads. You will

also solder an EC3 connector to each of the motor leads. Finally, you will solder EC3

connectors to each of the ESC leads that connect to the motor. The EC3 connectors will give

you the ability to switch around the wire connections when you check your motor direction

later in the build.

Be sure to follow the specified genders for all of the leads. The general rule is if a lead is

supplying power, then it will be a female connector. All connectors are eventually protected

with shrink tubing; hence female connectors will not accidentally short out if disconnected

from the mating male connector.

Please follow the instructions below.

1. Gather together your motors, the red 16 AWG wire, EC3 connectors, wire cutters,

wire stripper, ruler, and soldering supplies.

Figure 3.15 Motor set-screw adjustment.