Page 114 - Building A Succesful Board-Test Strategy

P. 114

100 BUILDING A SUCCESSFUL BOARD-TEST STRATEGY

Smaller parts

More complex parts

Denser boards

Ever-shrinking device-pin spacings

Increasing use of BGAs, flip-chips, and other technologies with hidden nodes

Increased use of expensive, low-volume boards for many products

Figure 3-2 These factors both encourage and discourage inspection as part of a "test'

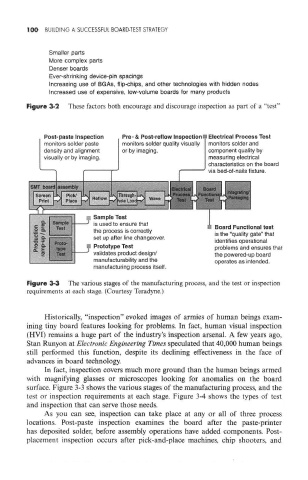

Figure 3-3 The various stages of the manufacturing process, and the test or inspection

requirements at each stage. (Courtesy Teradyne.)

Historically, "inspection" evoked images of armies of human beings exam-

ining tiny board features looking for problems. In fact, human visual inspection

(HVI) remains a huge part of the industry's inspection arsenal. A few years ago,

Stan Runyon at Electronic Engineering Times speculated that 40,000 human beings

still performed this function, despite its declining effectiveness in the face of

advances in board technology.

In fact, inspection covers much more ground than the human beings armed

with magnifying glasses or microscopes looking for anomalies on the board

surface. Figure 3-3 shows the various stages of the manufacturing process, and the

test or inspection requirements at each stage. Figure 3-4 shows the types of test

and inspection that can serve those needs.

As you can see, inspection can take place at any or all of three process

locations. Post-paste inspection examines the board after the paste-printer

has deposited solder, before assembly operations have added components. Post-

placement inspection occurs after pick-and-place machines, chip shooters, and