Page 252 - Buried Pipe Design

P. 252

226 Chapter Four

Liner classification:

■ Class A: No liner

■ Class B: Polyester resin—nonreinforced

■ Class C: Epoxy resin—nonreinforced

■ Class D: Phenolic resin—nonreinforced

■ Class E: Polyester resin—reinforced

■ Class F: Epoxy resin—reinforced

■ Class G: Phenolic resin—reinforced

■ Class H: Thermoplastic resin liner (specify)

■ Class I: Furan resin liner—reinforced

ASTM D 2992 is the standard method for obtaining hydrostatic

design basis for reinforced thermosetting resin pipe and fittings. There

are two procedures:

1. Procedure A: cyclic strength. This procedure is based on pipe failure

at a minimum of 150 10 cycles at 25 cycles/min, 11.4 years.

6

2. Procedure B: static strength. This procedure is based on pipe fail-

ure at a minimum 100,000 h (11.4 years) of static pressure.

It is important to note that ASTM does not specify a service factor

for RTR pipe. Therefore, it is up to the design engineer to determine

the hydrostatic design basis to be used for a particular pipe. The prod-

uct designation code, the manufacturer’s product data, and ASTM

standards make it easy to determine what safety factor is being

employed at the recommended working pressure.

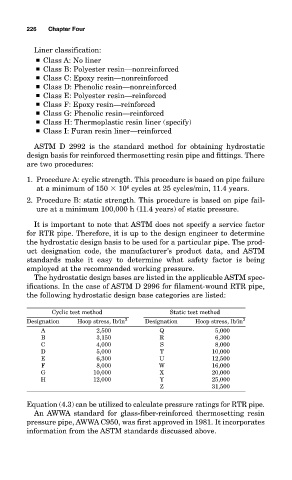

The hydrostatic design bases are listed in the applicable ASTM spec-

ifications. In the case of ASTM D 2996 for filament-wound RTR pipe,

the following hydrostatic design base categories are listed:

Cyclic test method Static test method

Designation Hoop stress, lb/in 2 Designation Hoop stress, lb/in 2

A 2,500 Q 5,000

B 3,150 R 6,300

C 4,000 S 8,000

D 5,000 T 10,000

E 6,300 U 12,500

F 8,000 W 16,000

G 10,000 X 20,000

H 12,000 Y 25,000

Z 31,500

Equation (4.3) can be utilized to calculate pressure ratings for RTR pipe.

An AWWA standard for glass-fiber-reinforced thermosetting resin

pressure pipe, AWWA C950, was first approved in 1981. It incorporates

information from the ASTM standards discussed above.