Page 171 - Carbon Nanotube Fibres and Yarns

P. 171

162 Carbon Nanotube Fibers and Yarns

80 20

70 18

16

Tenacity (cN/tex) 50 Specific modulus (N/tex) 12 8

60

14

10

40

30

20 6 4

10 2

0

0 0 10 20 30 40 50 60

(A) 0 10 20 30 40 50 60 (B)

Surface twist angle (degrees) Surface twist angle (degrees)

60 90

Twisted

50 Untwisted 80

Trend-twisted 70

Trend-twist-untwisted

40 60

Yarn diameter (mm) 30 Tenacity (cN/tex) 40 Twisted

50

30

20

Untwisted

20

Trend-twisted

10

0 10 0 Trend-twist-untwisted

0 10,000 20,000 30,000 0 10,000 20,000 30,000

(C) Twist or false twist (T/m) (D) Twist or false twist (T/m)

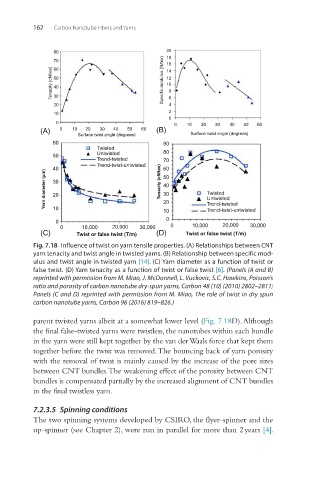

Fig. 7.18 Influence of twist on yarn tensile properties. (A) Relationships between CNT

yarn tenacity and twist angle in twisted yarns. (B) Relationship between specific mod-

ulus and twist angle in twisted yarn [14]. (C) Yarn diameter as a function of twist or

false twist. (D) Yarn tenacity as a function of twist or false twist [6]. (Panels (A and B)

reprinted with permission from M. Miao, J. McDonnell, L. Vuckovic, S.C. Hawkins, Poisson’s

ratio and porosity of carbon nanotube dry-spun yarns, Carbon 48 (10) (2010) 2802–2811;

Panels (C and D) reprinted with permission from M. Miao, The role of twist in dry spun

carbon nanotube yarns, Carbon 96 (2016) 819–826.)

parent twisted yarns albeit at a somewhat lower level (Fig. 7.18D). Although

the final false-twisted yarns were twistless, the nanotubes within each bundle

in the yarn were still kept together by the van der Waals force that kept them

together before the twist was removed. The bouncing back of yarn porosity

with the removal of twist is mainly caused by the increase of the pore sizes

between CNT bundles. The weakening effect of the porosity between CNT

bundles is compensated partially by the increased alignment of CNT bundles

in the final twistless yarn.

7.2.3.5 Spinning conditions

The two spinning systems developed by CSIRO, the flyer-spinner and the

up-spinner (see Chapter 2), were run in parallel for more than 2 years [4].