Page 175 - Carbon Nanotube Fibres and Yarns

P. 175

166 Carbon Nanotube Fibers and Yarns

2000 800

Conductivity

Strength 600

Average strength (MPa) 1000 400 Electrical conducitivity (S/cm)

1500

500

200

0 0

NMP

Water

(A) Dry-spun Cyclohexane Styrene Glycerin Ethanol Ethylene glycol Acetone DMF DMSO

Toluene

n-Hexane

Methanol

Acetonitrile

Ethyl acetate

Cyclohexene

1,3–propanediol

3.0

Specific strength (N/tex) 1.8

2.4

1.2

0.6

0.0

(B) Pristine NMP0%NMP7%CSA0%CSA7%CSA13%

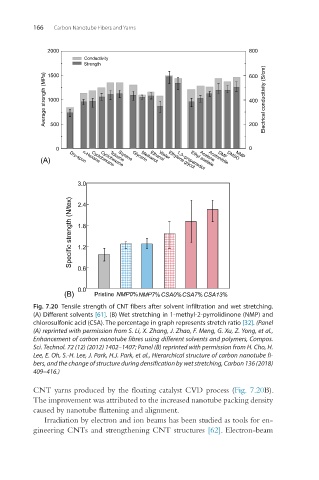

Fig. 7.20 Tensile strength of CNT fibers after solvent infiltration and wet stretching.

(A) Different solvents [61]. (B) Wet stretching in 1-methyl-2-pyrrolidinone (NMP) and

chlorosulfonic acid (CSA). The percentage in graph represents stretch ratio [32]. (Panel

(A) reprinted with permission from S. Li, X. Zhang, J. Zhao, F. Meng, G. Xu, Z. Yong, et al.,

Enhancement of carbon nanotube fibres using different solvents and polymers, Compos.

Sci. Technol. 72 (12) (2012) 1402–1407; Panel (B) reprinted with permission from H. Cho, H.

Lee, E. Oh, S.-H. Lee, J. Park, H.J. Park, et al., Hierarchical structure of carbon nanotube fi-

bers, and the change of structure during densification by wet stretching, Carbon 136 (2018)

409–416.)

CNT yarns produced by the floating catalyst CVD process (Fig. 7.20B).

The improvement was attributed to the increased nanotube packing density

caused by nanotube flattening and alignment.

Irradiation by electron and ion beams has been studied as tools for en-

gineering CNTs and strengthening CNT structures [62]. Electron-beam