Page 297 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 297

260 Carraher’s Polymer Chemistry

Composites

Particle-reinforced Fiber-reinforced Structural

Large particle Continuous Discontinuous Laminates Sandwich

(short)

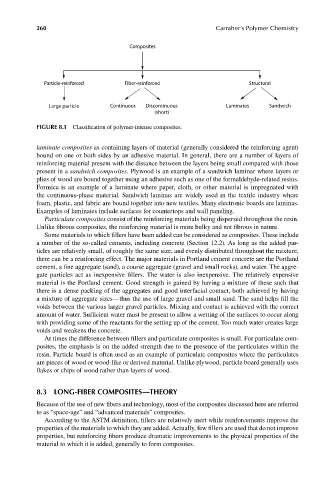

FIGURE 8.1 Classification of polymer-intense composites.

laminate composites as containing layers of material (generally considered the reinforcing agent)

bound on one or both sides by an adhesive material. In general, there are a number of layers of

reinforcing material present with the distance between the layers being small compared with those

present in a sandwich composites. Plywood is an example of a sandwich laminar where layers or

plies of wood are bound together using an adhesive such as one of the formaldehyde-related resins.

Formica is an example of a laminate where paper, cloth, or other material is impregnated with

the continuous-phase material. Sandwich laminas are widely used in the textile industry where

foam, plastic, and fabric are bound together into new textiles. Many electronic boards are laminas.

Examples of laminates include surfaces for countertops and wall paneling.

Particulate composites consist of the reinforcing materials being dispersed throughout the resin.

Unlike fibrous composites, the reinforcing material is more bulky and not fibrous in nature.

Some materials to which fillers have been added can be considered as composites. These include

a number of the so-called cements, including concrete (Section 12.2). As long as the added par-

ticles are relatively small, of roughly the same size, and evenly distributed throughout the mixture,

there can be a reinforcing effect. The major materials in Portland cement concrete are the Portland

cement, a fine aggregate (sand), a course aggregate (gravel and small rocks), and water. The aggre-

gate particles act as inexpensive fillers. The water is also inexpensive. The relatively expensive

material is the Portland cement. Good strength is gained by having a mixture of these such that

there is a dense packing of the aggregates and good interfacial contact, both achieved by having

a mixture of aggregate sizes—thus the use of large gravel and small sand. The sand helps fi ll the

voids between the various larger gravel particles. Mixing and contact is achieved with the correct

amount of water. Sufficient water must be present to allow a wetting of the surfaces to occur along

with providing some of the reactants for the setting up of the cement. Too much water creates large

voids and weakens the concrete.

At times the difference between fillers and particulate composites is small. For particulate com-

posites, the emphasis is on the added strength due to the presence of the particulates within the

resin. Particle board is often used as an example of particulate composites where the particulates

are pieces of wood or wood-like or derived material. Unlike plywood, particle board generally uses

flakes or chips of wood rather than layers of wood.

8.3 LONG-FIBER COMPOSITES—THEORY

Because of the use of new fibers and technology, most of the composites discussed here are referred

to as “space-age” and “advanced materials” composites.

According to the ASTM defi nition, fi llers are relatively inert while reinforcements improve the

properties of the materials to which they are added. Actually, few fillers are used that do not improve

properties, but reinforcing fibers produce dramatic improvements to the physical properties of the

material to which it is added, generally to form composites.

9/14/2010 3:40:26 PM

K10478.indb 260 9/14/2010 3:40:26 PM

K10478.indb 260