Page 299 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 299

262 Carraher’s Polymer Chemistry

Fiber

Resin matrix

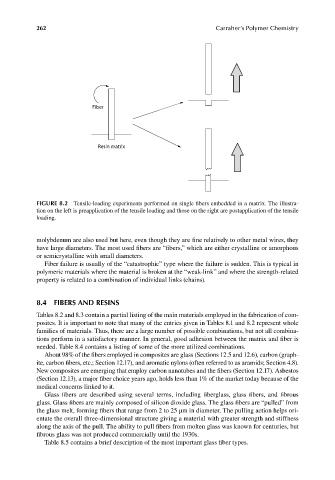

FIGURE 8.2 Tensile-loading experiments performed on single fibers embedded in a matrix. The illustra-

tion on the left is preapplication of the tensile loading and those on the right are postapplication of the tensile

loading.

molybdenum are also used but here, even though they are fine relatively to other metal wires, they

have large diameters. The most used fibers are “fibers,” which are either crystalline or amorphous

or semicrystalline with small diameters.

Fiber failure is usually of the “catastrophic” type where the failure is sudden. This is typical in

polymeric materials where the material is broken at the “weak-link” and where the strength-related

property is related to a combination of individual links (chains).

8.4 FIBERS AND RESINS

Tables 8.2 and 8.3 contain a partial listing of the main materials employed in the fabrication of com-

posites. It is important to note that many of the entries given in Tables 8.1 and 8.2 represent whole

families of materials. Thus, there are a large number of possible combinations, but not all combina-

tions perform in a satisfactory manner. In general, good adhesion between the matrix and fi ber is

needed. Table 8.4 contains a listing of some of the more utilized combinations.

About 98% of the fibers employed in composites are glass (Sections 12.5 and 12.6), carbon (graph-

ite, carbon fibers, etc.; Section 12.17), and aromatic nylons (often referred to as aramids; Section 4.8).

New composites are emerging that employ carbon nanotubes and the fibers (Section 12.17). Asbestos

(Section 12.13), a major fiber choice years ago, holds less than 1% of the market today because of the

medical concerns linked to it.

Glass fibers are described using several terms, including fiberglass, glass fibers, and fi brous

glass. Glass fibers are mainly composed of silicon dioxide glass. The glass fibers are “pulled” from

the glass melt, forming fibers that range from 2 to 25 μm in diameter. The pulling action helps ori-

entate the overall three-dimensional structure giving a material with greater strength and stiffness

along the axis of the pull. The ability to pull fibers from molten glass was known for centuries, but

fibrous glass was not produced commercially until the 1930s.

Table 8.5 contains a brief description of the most important glass fi ber types.

9/14/2010 3:40:27 PM

K10478.indb 262 9/14/2010 3:40:27 PM

K10478.indb 262