Page 304 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 304

Composites and Fillers 267

apart. Composite assemblies have a minimum of fl exibility. To discourage refl ections in unwanted

directions, the electrical continuity is maintained over the entire surface of the bomber. Thus, all

moving and major body parts are tight fitting. The composite nature of the outer skin allows this to

be closely achieved.

The engines are buried deep within the aircrafts interior, reducing noise and “heat signature.”

The heat signature is further reduced by mixing the jet’s exhaust with cooled air and exiting it

through slit-like vents.

Stealth aircraft are often painted a medium gray or bluish gray that matches the sky so that is

does not stand out. Coatings are composed of RAM that penetrates into cracks, reducing the num-

ber of minor repairs and use of special tape for repair. Every screw, panel, seam, and gap is covered

with a special tape or the RAM coating adding to the bomber’s stealthiness.

Because most traditional polymers have low dielectric constants, they can be used as RAMs

and many have been used in various applications in military and civil applications. While the B-2

largely depends on a graphite carbon-impregnated composite for its integrity and stealthiness, many

other polymers are used as RAMs. Many of these are various elastomeric materials. Neoprene is

widely used in naval applications as a RAM because of its good weather resistance. Nitrile is used

for fuel and oil resistance and fluoroelastomers are used where wide temperature ranges are encoun-

tered. Often, thin fl exible sheets or layers of the elastomer are adhered to a metal substrate. While

the polysiloxanes offer good RAM behavior, they are difficult to adhere to many metal structures

and thus, are not as widely employed in comparison to neoprene and nitrile rubbers. Products are

also made using various molding methods. To improve weather resistance, the absorber is often

painted with another RAM, an epoxy or urethane-based coating.

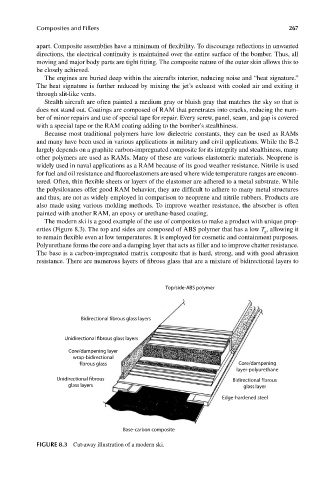

The modern ski is a good example of the use of composites to make a product with unique prop-

erties (Figure 8.3). The top and sides are composed of ABS polymer that has a low T , allowing it

g

to remain flexible even at low temperatures. It is employed for cosmetic and containment purposes.

Polyurethane forms the core and a damping layer that acts as filler and to improve chatter resistance.

The base is a carbon-impregnated matrix composite that is hard, strong, and with good abrasion

resistance. There are numerous layers of fibrous glass that are a mixture of bidirectional layers to

Top/side-ABS polymer

Bidirectional fibrous glass layers

Unidirectional fibrous glass layers

Core/dampening layer

wrap-bidirectional

fibrous glass Core/dampening

layer-polyurethane

Unidirectional fibrous Bidirectional fibrous

glass layers glass layer

Edge-hardened steel

Base-carbon composite

FIGURE 8.3 Cut-away illustration of a modern ski.

9/14/2010 3:40:28 PM

K10478.indb 267 9/14/2010 3:40:28 PM

K10478.indb 267