Page 307 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 307

270 Carraher’s Polymer Chemistry

Na + +

+ Na + Na

Na Na +

+

+ Na +

Na Na + Na

+ +

Na Na + Na

Na +

+ +

Na Na

H O - - - +

2

Na + Na

+

Na Na +

+

Na +

Na + Na + Na Na +

+

Na + Na +

Na +

+ Na

Na

+

Na Na +

Na +

+ +

Na Na

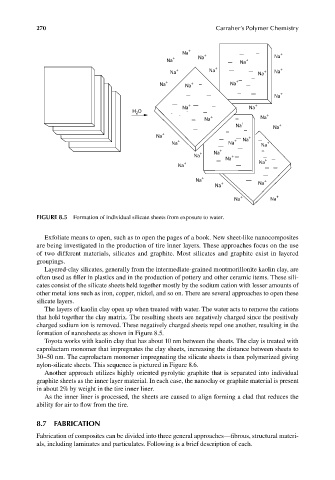

FIGURE 8.5 Formation of individual silicate sheets from exposure to water.

Exfoliate means to open, such as to open the pages of a book. New sheet-like nanocomposites

are being investigated in the production of tire inner layers. These approaches focus on the use

of two different materials, silicates and graphite. Most silicates and graphite exist in layered

groupings.

Layered-clay silicates, generally from the intermediate-grained montmorillonite kaolin clay, are

often used as filler in plastics and in the production of pottery and other ceramic items. These sili-

cates consist of the silicate sheets held together mostly by the sodium cation with lesser amounts of

other metal ions such as iron, copper, nickel, and so on. There are several approaches to open these

silicate layers.

The layers of kaolin clay open up when treated with water. The water acts to remove the cations

that hold together the clay matrix. The resulting sheets are negatively charged since the positively

charged sodium ion is removed. These negatively charged sheets repel one another, resulting in the

formation of nanosheets as shown in Figure 8.5.

Toyota works with kaolin clay that has about 10 nm between the sheets. The clay is treated with

caprolactam monomer that impregnates the clay sheets, increasing the distance between sheets to

30–50 nm. The caprolactam monomer impregnating the silicate sheets is then polymerized giving

nylon-silicate sheets. This sequence is pictured in Figure 8.6.

Another approach utilizes highly oriented pyrolytic graphite that is separated into individual

graphite sheets as the inner layer material. In each case, the nanoclay or graphite material is present

in about 2% by weight in the tire inner liner.

As the inner liner is processed, the sheets are caused to align forming a clad that reduces the

ability for air to flow from the tire.

8.7 FABRICATION

Fabrication of composites can be divided into three general approaches—fibrous, structural materi-

als, including laminates and particulates. Following is a brief description of each.

9/14/2010 3:40:30 PM

K10478.indb 270 9/14/2010 3:40:30 PM

K10478.indb 270