Page 539 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 539

502 Carraher’s Polymer Chemistry

Load

Indentor

Sample

Holder

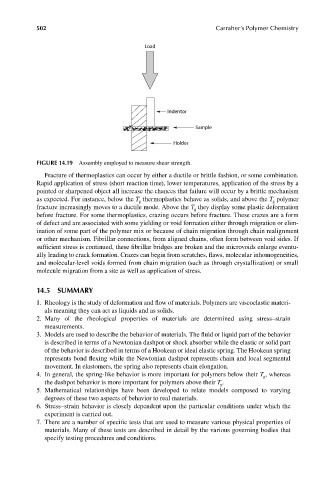

FIGURE 14.19 Assembly employed to measure shear strength.

Fracture of thermoplastics can occur by either a ductile or brittle fashion, or some combination.

Rapid application of stress (short reaction time), lower temperatures, application of the stress by a

pointed or sharpened object all increase the chances that failure will occur by a brittle mechanism

as expected. For instance, below the T thermoplastics behave as solids, and above the T polymer

g

g

fracture increasingly moves to a ductile mode. Above the T they display some plastic deformation

g

before fracture. For some thermoplastics, crazing occurs before fracture. These crazes are a form

of defect and are associated with some yielding or void formation either through migration or elim-

ination of some part of the polymer mix or because of chain migration through chain realignment

or other mechanism. Fibrillar connections, from aligned chains, often form between void sides. If

sufficient stress is continued, these fibrillar bridges are broken and the microvoids enlarge eventu-

ally leading to crack formation. Crazes can begin from scratches, flaws, molecular inhomogeneities,

and molecular-level voids formed from chain migration (such as through crystallization) or small

molecule migration from a site as well as application of stress.

14.5 SUMMARY

1. Rheology is the study of deformation and flow of materials. Polymers are viscoelastic materi-

als meaning they can act as liquids and as solids.

2. Many of the rheological properties of materials are determined using stress–strain

measurements.

3. Models are used to describe the behavior of materials. The fluid or liquid part of the behavior

is described in terms of a Newtonian dashpot or shock absorber while the elastic or solid part

of the behavior is described in terms of a Hookean or ideal elastic spring. The Hookean spring

represents bond flexing while the Newtonian dashpot represents chain and local segmental

movement. In elastomers, the spring also represents chain elongation.

4. In general, the spring-like behavior is more important for polymers below their T , whereas

g

the dashpot behavior is more important for polymers above their T .

g

5. Mathematical relationships have been developed to relate models composed to varying

degrees of these two aspects of behavior to real materials.

6. Stress–strain behavior is closely dependent upon the particular conditions under which the

experiment is carried out.

7. There are a number of specific tests that are used to measure various physical properties of

materials. Many of these tests are described in detail by the various governing bodies that

specify testing procedures and conditions.

9/14/2010 3:42:42 PM

K10478.indb 502 9/14/2010 3:42:42 PM

K10478.indb 502