Page 546 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 546

Additives 509

plasticizers are of this grouping. Performance plasticizers offer added performance over general

purpose plasticizers generally with added cost. Performance plasticizers include fast solvating

materials such as butyl benzyl phthalate and dihexyl phthalate; low temperature plasticizers such

as di-n-undecyl phthalate and di-2-ethylhexyl adipate; and so-called permanent plasticizers such as

tri-2-ethylhexyl trimellitate (TOTM), triisononyl trimellitate, and diisodecyl phthalate. Specialty

plasticizers include materials that provide important properties such as reduced migration, improved

stress–strain behavior, flame resistance, and increased stabilization.

The three main chemical groups of plasticizers are phthalate esters, trimellitate esters, and adi-

pate esters. In all three cases, performance is varied through the introduction of different alcohols

into the final plasticizer product. There is a balance between compatibility and migration. Generally,

the larger the ester grouping the less the migration up to a point where compatibility becomes a

problem and where compatibility now becomes the limiting factor.

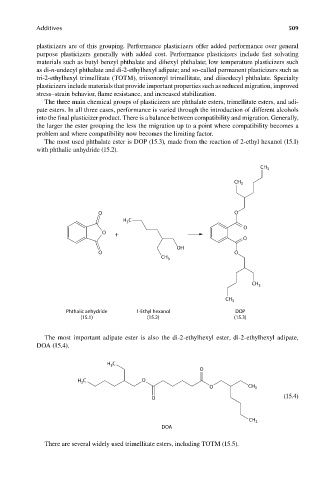

The most used phthalate ester is DOP (15.3), made from the reaction of 2-ethyl hexanol (15.1)

with phthalic anhydride (15.2).

CH 3

CH 3

O O

H C

3

O

O +

O

OH

O O

CH 3

CH 3

CH 3

Phthalic anhydride 1-Ethyl hexanol DOP

(15.1) (15.2) (15.3)

The most important adipate ester is also the di-2-ethylhexyl ester, di-2-ethylhexyl adipate,

DOA (15.4).

C

H 3

O

H C O

3

O CH 3

(15.4)

O

CH 3

DOA

There are several widely used trimellitate esters, including TOTM (15.5).

9/14/2010 3:42:43 PM

K10478.indb 509

K10478.indb 509 9/14/2010 3:42:43 PM