Page 622 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 622

Polymer Technology 585

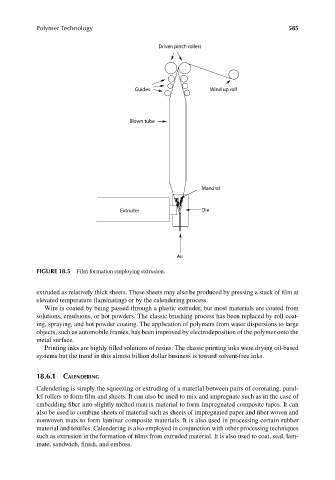

Driven pinch rollers

Guides Wind up roll

Blown tube

Mandrel

Extruder Die

Air

FIGURE 18.5 Film formation employing extrusion.

extruded as relatively thick sheets. These sheets may also be produced by pressing a stack of fi lm at

elevated temperature (laminating) or by the calendering process.

Wire is coated by being passed through a plastic extruder, but most materials are coated from

solutions, emulsions, or hot powders. The classic brushing process has been replaced by roll coat-

ing, spraying, and hot powder coating. The application of polymers from water dispersions to large

objects, such as automobile frames, has been improved by electrodeposition of the polymer onto the

metal surface.

Printing inks are highly filled solutions of resins. The classic printing inks were drying oil-based

systems but the trend in this almost billion dollar business is toward solvent-free inks.

18.6.1 CALENDERING

Calendering is simply the squeezing or extruding of a material between pairs of corotating, paral-

lel rollers to form film and sheets. It can also be used to mix and impregnate such as in the case of

embedding fiber into slightly melted matrix material to form impregnated composite tapes. It can

also be used to combine sheets of material such as sheets of impregnated paper and fiber woven and

nonwoven mats to form laminar composite materials. It is also used in processing certain rubber

material and textiles. Calendering is also employed in conjunction with other processing techniques

such as extrusion in the formation of films from extruded material. It is also used to coat, seal, lam-

inate, sandwich, finish, and emboss.

9/14/2010 3:43:38 PM

K10478.indb 585 9/14/2010 3:43:38 PM

K10478.indb 585