Page 620 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 620

Polymer Technology 583

Polymerization Coagulation

Monomers for Raw material Natural rubber

elastomer latex

Mastication

Compounding

Unvulcanized stock Additives

Shaping-molding/forming

Formed stock

Vulcanization

Elastomer

(Any needed additional)

Finishing

Finished product

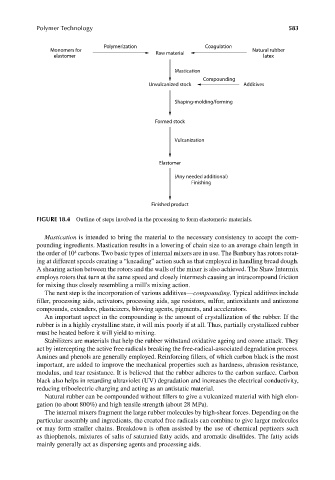

FIGURE 18.4 Outline of steps involved in the processing to form elastomeric materials.

Mastication is intended to bring the material to the necessary consistency to accept the com-

pounding ingredients. Mastication results in a lowering of chain size to an average chain length in

4

the order of 10 carbons. Two basic types of internal mixers are in use. The Banbury has rotors rotat-

ing at different speeds creating a “kneading” action such as that employed in handling bread dough.

A shearing action between the rotors and the walls of the mixer is also achieved. The Shaw Intermix

employs rotors that turn at the same speed and closely intermesh causing an intracompound friction

for mixing thus closely resembling a mill’s mixing action.

The next step is the incorporation of various additives—compounding. Typical additives include

filler, processing aids, activators, processing aids, age resistors, sulfur, antioxidants and antiozone

compounds, extenders, plasticizers, blowing agents, pigments, and accelerators.

An important aspect in the compounding is the amount of crystallization of the rubber. If the

rubber is in a highly crystalline state, it will mix poorly if at all. Thus, partially crystallized rubber

must be heated before it will yield to mixing.

Stabilizers are materials that help the rubber withstand oxidative ageing and ozone attack. They

act by intercepting the active free radicals breaking the free-radical-associated degradation process.

Amines and phenols are generally employed. Reinforcing fillers, of which carbon black is the most

important, are added to improve the mechanical properties such as hardness, abrasion resistance,

modulus, and tear resistance. It is believed that the rubber adheres to the carbon surface. Carbon

black also helps in retarding ultraviolet (UV) degradation and increases the electrical conductivity,

reducing triboelectric charging and acting as an antistatic material.

Natural rubber can be compounded without fillers to give a vulcanized material with high elon-

gation (to about 800%) and high tensile strength (about 28 MPa).

The internal mixers fragment the large rubber molecules by high-shear forces. Depending on the

particular assembly and ingredients, the created free radicals can combine to give larger molecules

or may form smaller chains. Breakdown is often assisted by the use of chemical peptizers such

as thiophenols, mixtures of salts of saturated fatty acids, and aromatic disulfides. The fatty acids

mainly generally act as dispersing agents and processing aids.

9/14/2010 3:43:37 PM

K10478.indb 583 9/14/2010 3:43:37 PM

K10478.indb 583