Page 615 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 615

578 Carraher’s Polymer Chemistry

Polymer solidifies as

(a) Melt spinning

it cools

Melted polymer

Spinneret

Hot gas to remove solvent

(b) Solvent spinning

Dissolved polymer

(c) Wet spinning

Hot gas

Dissolved polymer

Spinneret

Nonsolvent bath

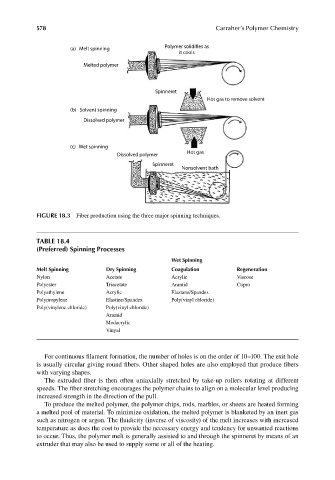

FIGURE 18.3 Fiber production using the three major spinning techniques.

TABLE 18.4

(Preferred) Spinning Processes

Wet Spinning

Melt Spinning Dry Spinning Coagulation Regeneration

Nylon Acetate Acrylic Viscose

Polyester Triacetate Aramid Cupro

Polyethylene Acrylic Elastane/Spandex

Polypropylene Elastine/Spandex Poly(vinyl chloride)

Poly(vinylene chloride) Poly(vinyl chloride)

Aramid

Modacrylic

Vinyal

For continuous filament formation, the number of holes is on the order of 10–100. The exit hole

is usually circular giving round fibers. Other shaped holes are also employed that produce fi bers

with varying shapes.

The extruded fiber is then often uniaxially stretched by take-up rollers rotating at different

speeds. The fiber stretching encourages the polymer chains to align on a molecular level producing

increased strength in the direction of the pull.

To produce the melted polymer, the polymer chips, rods, marbles, or sheets are heated forming

a melted pool of material. To minimize oxidation, the melted polymer is blanketed by an inert gas

such as nitrogen or argon. The fl uidicity (inverse of viscosity) of the melt increases with increased

temperature as does the cost to provide the necessary energy and tendency for unwanted reactions

to occur. Thus, the polymer melt is generally assisted to and through the spinneret by means of an

extruder that may also be used to supply some or all of the heating.

9/14/2010 3:43:36 PM

K10478.indb 578 9/14/2010 3:43:36 PM

K10478.indb 578