Page 611 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 611

574 Carraher’s Polymer Chemistry

• Movement of the resin to the shaping apparatus through application of heat and/or pressure

and other flow aiding processes, and

• Removal and recycling of unwanted solvent, unreacted monomer(s), byproducts, and waste (fl ash)

The shaping step may include any single or combination of the following:

• Die forming (including sheet and film formation, tube and pipe formation, fi ber formation,

coating, and extrusion)

• Molding and casting

• Secondary shaping (such as film and blow molding, thermoforming), and

• Surface treatments (coating and calendering)

Postshaping processes include welding, bonding, fastening, decorating, cutting, milling, drilling,

dying, and gluing.

Polymer processing operations can be divided into five broad categories:

• Spinning (generally for fi bers)

• Calendering

• Coating

• Molding, and

• Injection

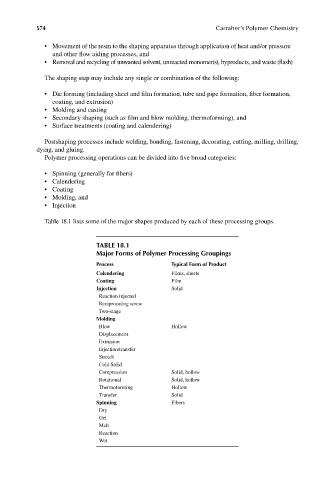

Table 18.1 lists some of the major shapes produced by each of these processing groups.

TABLE 18.1

Major Forms of Polymer Processing Groupings

Process Typical Form of Product

Calendering Films, sheets

Coating Film

Injection Solid

Reaction injected

Reciprocating screw

Two-stage

Molding

Blow Hollow

Displacement

Extrusion

Injection/transfer

Stretch

Cold Solid

Compression Solid, hollow

Rotational Solid, hollow

Thermoforming Hollow

Transfer Solid

Spinning Fibers

Dry

Gel

Melt

Reaction

Wet

9/14/2010 3:43:35 PM

K10478.indb 574 9/14/2010 3:43:35 PM

K10478.indb 574