Page 638 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 638

Polymer Technology 601

R R

R R

O O

O O

HC

3

HC

3

Ethyl acrylate derived unit (18.1) Butyl acrylate derived unit (18.2)

The T of the copolymer must be below the application temperature to allow diffusion of water

g

from the latex to occur as it is drying forming the protective fi lm.

18.12.1 PROCESSING

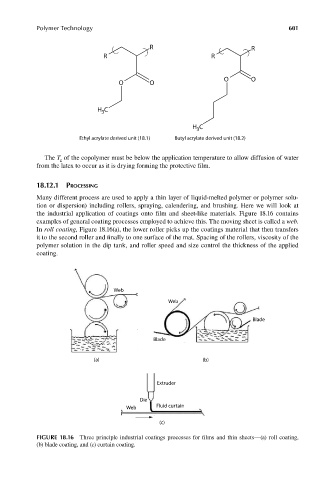

Many different process are used to apply a thin layer of liquid-melted polymer or polymer solu-

tion or dispersion) including rollers, spraying, calendering, and brushing. Here we will look at

the industrial application of coatings onto film and sheet-like materials. Figure 18.16 contains

examples of general coating processes employed to achieve this. The moving sheet is called a web.

In roll coating, Figure 18.16(a), the lower roller picks up the coatings material that then transfers

it to the second roller and finally to one surface of the mat. Spacing of the rollers, viscosity of the

polymer solution in the dip tank, and roller speed and size control the thickness of the applied

coating.

Web

Web

Blade

Blade

(a) (b)

Extruder

Die

Web Fluid curtain

(c)

FIGURE 18.16 Three principle industrial coatings processes for films and thin sheets—(a) roll coating,

(b) blade coating, and (c) curtain coating.

9/14/2010 3:43:43 PM

K10478.indb 601

K10478.indb 601 9/14/2010 3:43:43 PM