Page 636 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 636

Polymer Technology 599

f e b a c

Screw

d

Barrel

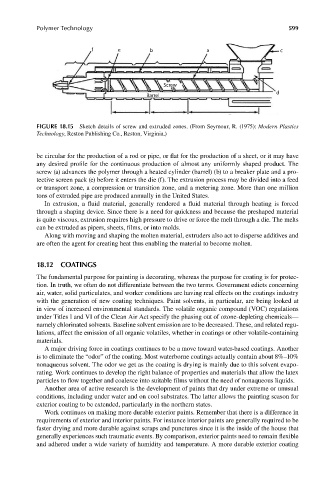

FIGURE 18.15 Sketch details of screw and extruded zones. (From Seymour, R. (1975): Modern Plastics

Technology, Reston Publishing Co., Reston, Virginia.)

be circular for the production of a rod or pipe, or flat for the production of a sheet, or it may have

any desired profile for the continuous production of almost any uniformly shaped product. The

screw (a) advances the polymer through a heated cylinder (barrel) (b) to a breaker plate and a pro-

tective screen pack (e) before it enters the die (f). The extrusion process may be divided into a feed

or transport zone, a compression or transition zone, and a metering zone. More than one million

tons of extruded pipe are produced annually in the United States.

In extrusion, a fluid material, generally rendered a fluid material through heating is forced

through a shaping device. Since there is a need for quickness and because the preshaped material

is quite viscous, extrusion requires high pressure to drive or force the melt through a die. The melts

can be extruded as pipers, sheets, films, or into molds.

Along with moving and shaping the molten material, extruders also act to disperse additives and

are often the agent for creating heat thus enabling the material to become molten.

18.12 COATINGS

The fundamental purpose for painting is decorating, whereas the purpose for coating is for protec-

tion. In truth, we often do not differentiate between the two terms. Government edicts concerning

air, water, solid particulates, and worker conditions are having real effects on the coatings industry

with the generation of new coating techniques. Paint solvents, in particular, are being looked at

in view of increased environmental standards. The volatile organic compound (VOC) regulations

under Titles I and VI of the Clean Air Act specify the phasing out of ozone-depleting chemicals—

namely chlorinated solvents. Baseline solvent emission are to be decreased. These, and related regu-

lations, affect the emission of all organic volatiles, whether in coatings or other volatile-containing

materials.

A major driving force in coatings continues to be a move toward water-based coatings. Another

is to eliminate the “odor” of the coating. Most waterborne coatings actually contain about 8%–10%

nonaqueous solvent. The odor we get as the coating is drying is mainly due to this solvent evapo-

rating. Work continues to develop the right balance of properties and materials that allow the latex

particles to flow together and coalesce into suitable films without the need of nonaqueous liquids.

Another area of active research is the development of paints that dry under extreme or unusual

conditions, including under water and on cool substrates. The latter allows the painting season for

exterior coating to be extended, particularly in the northern states.

Work continues on making more durable exterior paints. Remember that there is a difference in

requirements of exterior and interior paints. For instance interior paints are generally required to be

faster drying and more durable against scraps and punctures since it is the inside of the house that

generally experiences such traumatic events. By comparison, exterior paints need to remain fl exible

and adhered under a wide variety of humidity and temperature. A more durable exterior coating

9/14/2010 3:43:42 PM

K10478.indb 599 9/14/2010 3:43:42 PM

K10478.indb 599