Page 632 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 632

Polymer Technology 595

Applied pressure

Sample and mold cavity

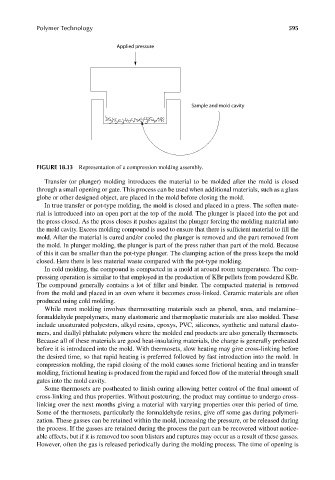

FIGURE 18.13 Representation of a compression molding assembly.

Transfer (or plunger) molding introduces the material to be molded after the mold is closed

through a small opening or gate. This process can be used when additional materials, such as a glass

globe or other designed object, are placed in the mold before closing the mold.

In true transfer or pot-type molding, the mold is closed and placed in a press. The soften mate-

rial is introduced into an open port at the top of the mold. The plunger is placed into the pot and

the press closed. As the press closes it pushes against the plunger forcing the molding material into

the mold cavity. Excess molding compound is used to ensure that there is sufficient material to fi ll the

mold. After the material is cured and/or cooled the plunger is removed and the part removed from

the mold. In plunger molding, the plunger is part of the press rather than part of the mold. Because

of this it can be smaller than the pot-type plunger. The clamping action of the press keeps the mold

closed. Here there is less material waste compared with the pot-type molding.

In cold molding, the compound is compacted in a mold at around room temperature. The com-

pressing operation is similar to that employed in the production of KBr pellets from powdered KBr.

The compound generally contains a lot of filler and binder. The compacted material is removed

from the mold and placed in an oven where it becomes cross-linked. Ceramic materials are often

produced using cold molding.

While most molding involves thermosetting materials such as phenol, urea, and melamine–

formaldehyde prepolymers, many elastomeric and thermoplastic materials are also molded. These

include unsaturated polyesters, alkyd resins, epoxys, PVC, silicones, synthetic and natural elasto-

mers, and diallyl phthalate polymers where the molded end products are also generally thermosets.

Because all of these materials are good heat-insulating materials, the charge is generally preheated

before it is introduced into the mold. With thermosets, slow heating may give cross-linking before

the desired time, so that rapid heating is preferred followed by fast introduction into the mold. In

compression molding, the rapid closing of the mold causes some frictional heating and in transfer

molding, frictional heating is produced from the rapid and forced flow of the material through small

gates into the mold cavity.

Some thermosets are postheated to finish curing allowing better control of the final amount of

cross-linking and thus properties. Without postcuring, the product may continue to undergo cross-

linking over the next months giving a material with varying properties over this period of time.

Some of the thermosets, particularly the formaldehyde resins, give off some gas during polymeri-

zation. These gasses can be retained within the mold, increasing the pressure, or be released during

the process. If the gasses are retained during the process the part can be recovered without notice-

able effects, but if it is removed too soon blisters and ruptures may occur as a result of these gasses.

However, often the gas is released periodically during the molding process. The time of opening is

9/14/2010 3:43:41 PM

K10478.indb 595

K10478.indb 595 9/14/2010 3:43:41 PM