Page 628 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 628

Polymer Technology 591

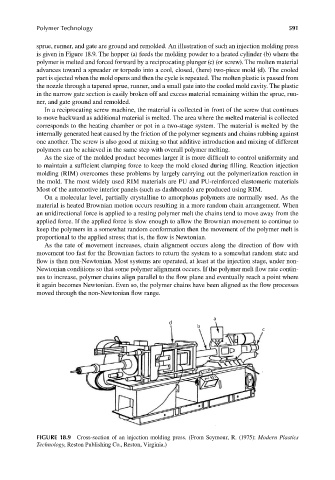

sprue, runner, and gate are ground and remolded. An illustration of such an injection molding press

is given in Figure 18.9. The hopper (a) feeds the molding powder to a heated cylinder (b) where the

polymer is melted and forced forward by a reciprocating plunger (c) (or screw). The molten material

advances toward a spreader or torpedo into a cool, closed, (here) two-piece mold (d). The cooled

part is ejected when the mold opens and then the cycle is repeated. The molten plastic is passed from

the nozzle through a tapered sprue, runner, and a small gate into the cooled mold cavity. The plastic

in the narrow gate section is easily broken off and excess material remaining within the sprue, run-

ner, and gate ground and remolded.

In a reciprocating screw machine, the material is collected in front of the screw that continues

to move backward as additional material is melted. The area where the melted material is collected

corresponds to the heating chamber or pot in a two-stage system. The material is melted by the

internally generated heat caused by the friction of the polymer segments and chains rubbing against

one another. The screw is also good at mixing so that additive introduction and mixing of different

polymers can be achieved in the same step with overall polymer melting.

As the size of the molded product becomes larger it is more difficult to control uniformity and

to maintain a sufficient clamping force to keep the mold closed during filling. Reaction injection

molding (RIM) overcomes these problems by largely carrying out the polymerization reaction in

the mold. The most widely used RIM materials are PU and PU-reinforced elastomeric materials

Most of the automotive interior panels (such as dashboards) are produced using RIM.

On a molecular level, partially crystalline to amorphous polymers are normally used. As the

material is heated Brownian motion occurs resulting in a more random chain arrangement. When

an unidirectional force is applied to a resting polymer melt the chains tend to move away from the

applied force. If the applied force is slow enough to allow the Brownian movement to continue to

keep the polymers in a somewhat random conformation then the movement of the polymer melt is

proportional to the applied stress; that is, the flow is Newtonian.

As the rate of movement increases, chain alignment occurs along the direction of fl ow with

movement too fast for the Brownian factors to return the system to a somewhat random state and

flow is then non-Newtonian. Most systems are operated, at least at the injection stage, under non-

Newtonian conditions so that some polymer alignment occurs. If the polymer melt flow rate contin-

ues to increase, polymer chains align parallel to the fl ow plane and eventually reach a point where

it again becomes Newtonian. Even so, the polymer chains have been aligned as the fl ow processes

moved through the non-Newtonian fl ow range.

a

d

b

c

FIGURE 18.9 Cross-section of an injection molding press. (From Seymour, R. (1975): Modern Plastics

Technology, Reston Publishing Co., Reston, Virginia.)

9/14/2010 3:43:40 PM

K10478.indb 591

K10478.indb 591 9/14/2010 3:43:40 PM