Page 630 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 630

Polymer Technology 593

Polymer injected Air injected

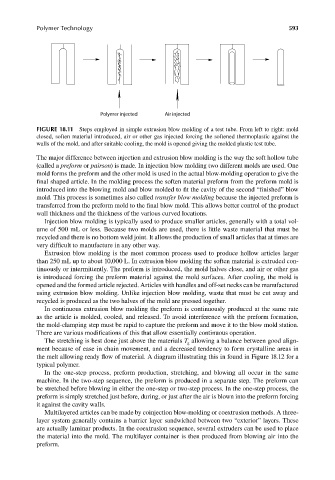

FIGURE 18.11 Steps employed in simple extrusion blow molding of a test tube. From left to right: mold

closed, soften material introduced, air or other gas injected forcing the softened thermoplastic against the

walls of the mold, and after suitable cooling, the mold is opened giving the molded plastic test tube.

The major difference between injection and extrusion blow molding is the way the soft hollow tube

(called a preform or pairson) is made. In injection blow molding two different molds are used. One

mold forms the preform and the other mold is used in the actual blow-molding operation to give the

final shaped article. In the molding process the soften material preform from the preform mold is

introduced into the blowing mold and blow molded to fit the cavity of the second “fi nished” blow

mold. This process is sometimes also called transfer blow molding because the injected preform is

transferred from the preform mold to the final blow mold. This allows better control of the product

wall thickness and the thickness of the various curved locations.

Injection blow molding is typically used to produce smaller articles, generally with a total vol-

ume of 500 mL or less. Because two molds are used, there is little waste material that must be

recycled and there is no bottom weld joint. It allows the production of small articles that at times are

very difficult to manufacture in any other way.

Extrusion blow molding is the most common process used to produce hollow articles larger

than 250 mL up to about 10,000 L. In extrusion blow molding the soften material is extruded con-

tinuously or intermittently. The preform is introduced, the mold halves close, and air or other gas

is introduced forcing the preform material against the mold surfaces. After cooling, the mold is

opened and the formed article rejected. Articles with handles and off-set necks can be manufactured

using extrusion blow molding. Unlike injection blow molding, waste that must be cut away and

recycled is produced as the two halves of the mold are pressed together.

In continuous extrusion blow molding the preform is continuously produced at the same rate

as the article is molded, cooled, and released. To avoid interference with the preform formation,

the mold-clamping step must be rapid to capture the preform and move it to the blow mold station.

There are various modifications of this that allow essentially continuous operation.

The stretching is best done just above the materials T allowing a balance between good align-

g

ment because of ease in chain movement, and a decreased tendency to form crystalline areas in

the melt allowing ready fl ow of material. A diagram illustrating this in found in Figure 18.12 for a

typical polymer.

In the one-step process, preform production, stretching, and blowing all occur in the same

machine. In the two-step sequence, the preform is produced in a separate step. The preform can

be stretched before blowing in either the one-step or two-step process. In the one-step process, the

preform is simply stretched just before, during, or just after the air is blown into the preform forcing

it against the cavity walls.

Multilayered articles can be made by coinjection blow-molding or coextrusion methods. A three-

layer system generally contains a barrier layer sandwiched between two “exterior” layers. These

are actually laminar products. In the coextrusion sequence, several extruders can be used to place

the material into the mold. The multilayer container is then produced from blowing air into the

preform.

9/14/2010 3:43:41 PM

K10478.indb 593

K10478.indb 593 9/14/2010 3:43:41 PM