Page 86 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 86

Polymer Structure (Morphology) 49

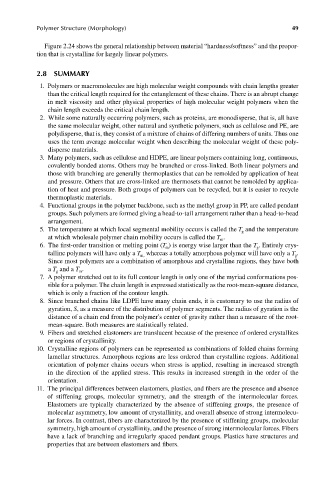

Figure 2.24 shows the general relationship between material “hardness/softness” and the propor-

tion that is crystalline for largely linear polymers.

2.8 SUMMARY

1. Polymers or macromolecules are high molecular weight compounds with chain lengths greater

than the critical length required for the entanglement of these chains. There is an abrupt change

in melt viscosity and other physical properties of high molecular weight polymers when the

chain length exceeds the critical chain length.

2. While some naturally occurring polymers, such as proteins, are monodisperse, that is, all have

the same molecular weight, other natural and synthetic polymers, such as cellulose and PE, are

polydisperse, that is, they consist of a mixture of chains of differing numbers of units. Thus one

uses the term average molecular weight when describing the molecular weight of these poly-

disperse materials.

3. Many polymers, such as cellulose and HDPE, are linear polymers containing long, continuous,

covalently bonded atoms. Others may be branched or cross-linked. Both linear polymers and

those with branching are generally thermoplastics that can be remolded by application of heat

and pressure. Others that are cross-linked are thermosets that cannot be remolded by applica-

tion of heat and pressure. Both groups of polymers can be recycled, but it is easier to recycle

thermoplastic materials.

4. Functional groups in the polymer backbone, such as the methyl group in PP, are called pendant

groups. Such polymers are formed giving a head-to-tail arrangement rather than a head-to-head

arrangement.

5. The temperature at which local segmental mobility occurs is called the T and the temperature

g

at which wholesale polymer chain mobility occurs is called the T .

m

6. The first-order transition or melting point (T ) is energy wise larger than the T . Entirely crys-

m g

talline polymers will have only a T whereas a totally amorphous polymer will have only a T .

m, g

Since most polymers are a combination of amorphous and crystalline regions, they have both

a T and a T .

g m

7. A polymer stretched out to its full contour length is only one of the myriad conformations pos-

sible for a polymer. The chain length is expressed statistically as the root-mean-square distance,

which is only a fraction of the contour length.

8. Since branched chains like LDPE have many chain ends, it is customary to use the radius of

gyration, S, as a measure of the distribution of polymer segments. The radius of gyration is the

distance of a chain end from the polymer’s center of gravity rather than a measure of the root-

mean-square. Both measures are statistically related.

9. Fibers and stretched elastomers are translucent because of the presence of ordered crystallites

or regions of crystallinity.

10. Crystalline regions of polymers can be represented as combinations of folded chains forming

lamellar structures. Amorphous regions are less ordered than crystalline regions. Additional

orientation of polymer chains occurs when stress is applied, resulting in increased strength

in the direction of the applied stress. This results in increased strength in the order of the

orientation.

11. The principal differences between elastomers, plastics, and fibers are the presence and absence

of stiffening groups, molecular symmetry, and the strength of the intermolecular forces.

Elastomers are typically characterized by the absence of stiffening groups, the presence of

molecular asymmetry, low amount of crystallinity, and overall absence of strong intermolecu-

lar forces. In contrast, fibers are characterized by the presence of stiffening groups, molecular

symmetry, high amount of crystallinity, and the presence of strong intermolecular forces. Fibers

have a lack of branching and irregularly spaced pendant groups. Plastics have structures and

properties that are between elastomers and fi bers.

9/14/2010 3:36:14 PM

K10478.indb 49 9/14/2010 3:36:14 PM

K10478.indb 49