Page 372 - Centrifugal Pumps 2E

P. 372

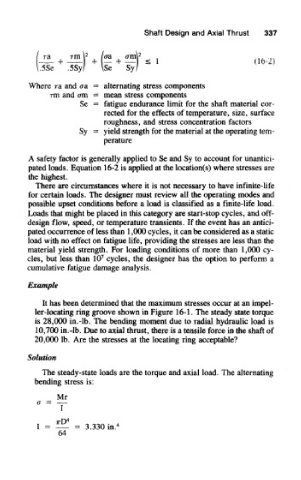

Shaft Design and Axial Thrust 337

Where ra and era = alternating stress components

rm and om = mean stress components

Se = fatigue endurance limit for the shaft material cor-

rected for the effects of temperature, size, surface

roughness, and stress concentration factors

Sy = yield strength for the material at the operating tem-

perature

A safety factor is generally applied to Se and Sy to account for unantici-

pated loads. Equation 16-2 is applied at the location(s) where stresses are

the highest.

There are circumstances where it is not necessary to have infinite-life

for certain loads. The designer must review all the operating modes and

possible upset conditions before a load is classified as a finite-life load.

Loads that might be placed in this category are start-stop cycles, and off-

design flow, speed, or temperature transients. If the event has an antici-

pated occurrence of less than 1,000 cycles, it can be considered as a static

load with no effect on fatigue life, providing the stresses are less than the

material yield strength. For loading conditions of more than 1,000 cy-

7

cles, but less than 10 cycles, the designer has the option to perform a

cumulative fatigue damage analysis.

Example

It has been determined that the maximum stresses occur at an impel-

ler-locating ring groove shown in Figure 16-1. The steady state torque

is 28,(XX) in.-lb. The bending moment due to radial hydraulic load is

10,700 in.-lb. Due to axial thrust, there is a tensile force in the shaft of

20,000 Ib. Are the stresses at the locating ring acceptable?

Solution

The steady-state loads are the torque and axial load. The alternating

bending stress is: