Page 422 - Centrifugal Pumps 2E

P. 422

386 Centrifugal Pumps: Design and Application

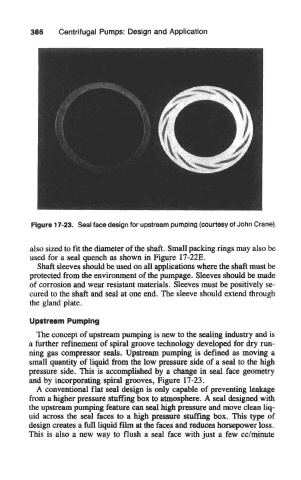

Flgyre 17-23. Seal face design for upstream pumping (courtesy of John Crane),

also sized to fit the diameter of the shaft. Small packing rings may also be

used for a seal quench as shown in Figure 17-22E.

Shaft sleeves should be used on all applications where the shaft must be

protected from the environment of the pumpage. Sleeves should be made

of corrosion and wear resistant materials. Sleeves must be positively se-

cured to the shaft and seal at one end. The sleeve should extend through

the gland plate.

Upstream Pumping

The concept of upstream pumping is new to the sealing industry and is

a further refinement of spiral groove technology developed for dry run-

ning gas compressor seals. Upstream pumping is defined as moving a

small quantity of liquid from the low pressure side of a seal to the high

pressure side. This is accomplished by a change in seal face geometry

and by incorporating spiral grooves, Figure 17-23.

A conventional flat seal design is only capable of preventing leakage

from a higher pressure stuffing box to atmosphere. A seal designed with

the upstream pumping feature can seal high pressure and move clean liq-

uid across the seal faces to a high pressure stuffing box. This type of

design creates a full liquid film at the faces and reduces horsepower loss.

This is also a new way to flush a seal face with just a few cc/minute