Page 423 - Centrifugal Pumps 2E

P. 423

Mechanical Seats 38?

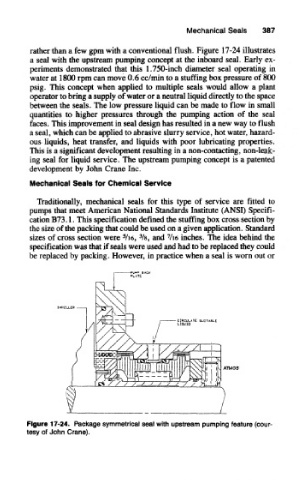

rather than a few gpm with a conventional flush. Figure 17-24 illustrates

a seal with the upstream pumping concept at the inboard seal. Early ex-

periments demonstrated that this 1.750-inch diameter seal operating in

water at 1800 rpm can move 0.6 cc/min to a stuffing box pressure of 800

psig. This concept when applied to multiple seals would allow a plant

operator to bring a supply of water or a neutral liquid directly to the space

between the seals. The low pressure liquid can be made to flow in small

quantities to higher pressures through the pumping action of the seal

faces. This improvement in seal design has resulted in a new way to flush

a seal, which can be applied to abrasive slurry service, hot water, hazard-

ous liquids, heat transfer, and liquids with poor lubricating properties.

This is a significant development resulting in a non-contacting, non-leak-

ing seal for liquid service. The upstream pumping concept is a patented

development by John Crane Inc.

Mechanical Seals for Chemical Service

Traditionally, mechanical seals for this type of service are fitted to

pumps that meet American National Standards Institute (ANSI) Specifi-

cation B73.1. This specification defined the stuffing box cross section by

the size of the packing that could be used on a given application. Standard

5 3 7

sizes of cross section were /i6, /s, and /i6 inches. The idea behind the

specification was that if seals were used and had to be replaced they could

be replaced by packing. However, in practice when a seal is worn out or

Figure 17-24. Package symmetrical seal with upstream pumping feature (cour-

tesy of John Crane).