Page 241 - Centrifugal Pumps Design and Application

P. 241

Double-Case Pumps 215

The throttle bushing bore, the shaft under the bushing, or both should

be grooved. To obtain the desired effect, the following design parameters

are varied: the groove cross section, the number of groove starts, the

"hand" of the grooves, and the length of the grooved section. The

grooves reduce leakage for a given running clearance and increase toler-

ance to solid particles in the feedwater. They also reduce the possibility

of seizure if the pump is subjected to severe operating transients, such as

flashing. Shaft sleeves under the throttle bushings are undesirable. They

reduce the ability to resist seizure during severe temperature transients,

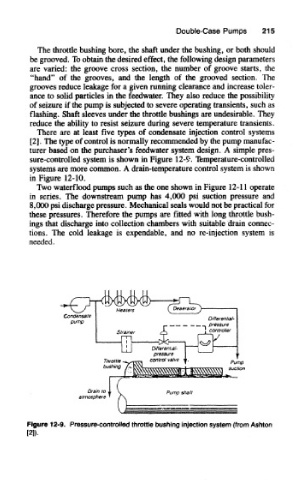

There are at least five types of condensate injection control systems

[2]. The type of control is normally recommended by the pump manufac-

turer based on the purchaser's feedwater system design. A simple pres-

sure-controlled system is shown in Figure 12-9. Temperature-controlled

systems are more common. A drain-temperature control system is shown

in Figure 12-10.

Two waterflood pumps such as the one shown in Figure 12-11 operate

in series. The downstream pump has 4,(XX) psi suction pressure and

8,(MX) psi discharge pressure. Mechanical seals would not be practical for

these pressures. Therefore the pumps are fitted with long throttle bush-

ings that discharge into collection chambers with suitable drain connec-

tions. The cold leakage is expendable, and no re-injection system Is

needed.

Figure 12-0. Pressure-controHed throttle bushing injection system (from Ashton

I2l).