Page 242 - Centrifugal Pumps Design and Application

P. 242

216 Centrifugal Pumps: Design and Application

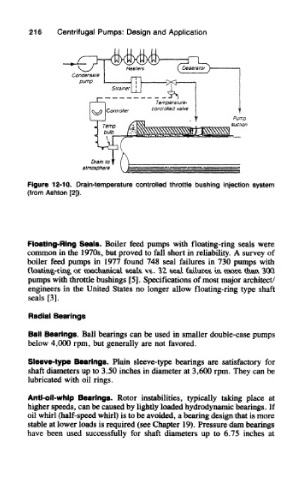

Figure 12-10. Drain-temperature controlled throttle bushing injection system

(from Ashton I2J).

Floating-Ring Seals. Boiler feed pumps with floating-ring seals were

common in the 1970s, but proved to fall short in reliability. A survey of

boiler feed pumps in 1977 found 748 seal failures in 730 pumps with

floating-ring or mechanical seals vs. 32 seal failures in more than 300

pumps with throttle bushings [5]. Specifications of most major architect/

engineers in the United States no longer allow floating-ring type shaft

seals [3J.

Radial Bearings

Bali Bearings. Ball bearings can be used in smaller double-case pumps

below 4,000 rpm, but generally are not favored.

Sleeve-type Bearings. Plain sleeve-type bearings are satisfactory for

shaft diameters up to 3.50 inches in diameter at 3,600 rpm. They can be

lubricated with oil rings.

Anti-oil-whip Bearings. Rotor instabilities, typically taking place at

higher speeds, can be caused by lightly loaded hydrodynamic bearings. If

oil whirl (half-speed whirl) is to be avoided, a bearing design that is more

stable at lower loads is required (see Chapter 19). Pressure dam bearings

have been used successfully for shaft diameters up to 6.75 inches at