Page 127 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 127

DATA COLLECTION AND ECONOMIC ANALYSIS 105

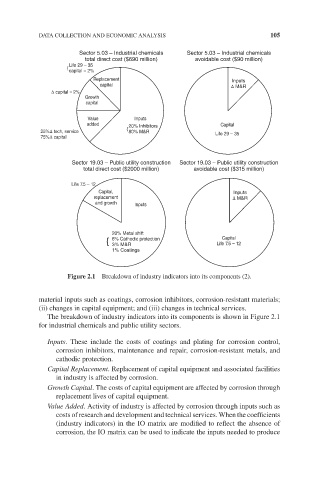

Sector 5.03 – Industrial chemicals Sector 5.03 – Industrial chemicals

total direct cost ($690 million) avoidable cost ($90 million)

Life 29 – 35

{

capital = 2%

Replacement Inputs

capital Δ M&R

Δ capital = 2%

Growth

capital

Value Inputs

added 20% Inhibitors Capital

{

25%Δ tech, service 80% M&R Life 29 – 35

75%Δ capital

Sector 19.03 – Public utility construction Sector 19.03 – Public utility construction

total direct cost ($2000 million) avoidable cost ($315 million)

Life 7.5 – 12

Capital, Inputs

replacement Δ M&R

and growth Inputs

20% Metal shift

6% Cathodic protection Capital

3% M&R Life 7.5 – 12

1% Coatings

Figure 2.1 Breakdown of industry indicators into its components (2).

material inputs such as coatings, corrosion inhibitors, corrosion-resistant materials;

(ii) changes in capital equipment; and (iii) changes in technical services.

The breakdown of industry indicators into its components is shown in Figure 2.1

for industrial chemicals and public utility sectors.

Inputs. These include the costs of coatings and plating for corrosion control,

corrosion inhibitors, maintenance and repair, corrosion-resistant metals, and

cathodic protection.

Capital Replacement. Replacement of capital equipment and associated facilities

in industry is affected by corrosion.

Growth Capital. The costs of capital equipment are affected by corrosion through

replacement lives of capital equipment.

Value Added. Activity of industry is affected by corrosion through inputs such as

costs of research and development and technical services. When the coefficients

(industry indicators) in the IO matrix are modified to reflect the absence of

corrosion, the IO matrix can be used to indicate the inputs needed to produce