Page 199 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 199

CHEMICAL, PETROCHEMICAL, AND PHARMACEUTICAL INDUSTRIES 177

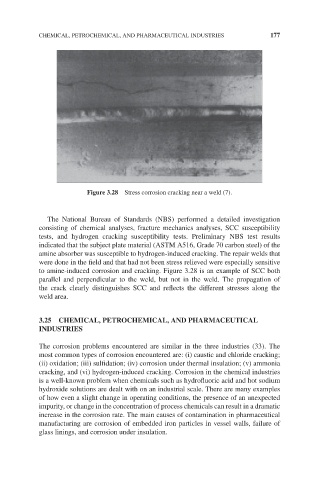

Figure 3.28 Stress corrosion cracking near a weld (7).

The National Bureau of Standards (NBS) performed a detailed investigation

consisting of chemical analyses, fracture mechanics analyses, SCC susceptibility

tests, and hydrogen cracking susceptibility tests. Preliminary NBS test results

indicated that the subject plate material (ASTM A516, Grade 70 carbon steel) of the

amine absorber was susceptible to hydrogen-induced cracking. The repair welds that

were done in the field and that had not been stress relieved were especially sensitive

to amine-induced corrosion and cracking. Figure 3.28 is an example of SCC both

parallel and perpendicular to the weld, but not in the weld. The propagation of

the crack clearly distinguishes SCC and reflects the different stresses along the

weld area.

3.25 CHEMICAL, PETROCHEMICAL, AND PHARMACEUTICAL

INDUSTRIES

The corrosion problems encountered are similar in the three industries (33). The

most common types of corrosion encountered are: (i) caustic and chloride cracking;

(ii) oxidation; (iii) sulfidation; (iv) corrosion under thermal insulation; (v) ammonia

cracking, and (vi) hydrogen-induced cracking. Corrosion in the chemical industries

is a well-known problem when chemicals such as hydrofluoric acid and hot sodium

hydroxide solutions are dealt with on an industrial scale. There are many examples

of how even a slight change in operating conditions, the presence of an unexpected

impurity, or change in the concentration of process chemicals can result in a dramatic

increase in the corrosion rate. The main causes of contamination in pharmaceutical

manufacturing are corrosion of embedded iron particles in vessel walls, failure of

glass linings, and corrosion under insulation.