Page 206 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 206

184 CORROSION CAUSES

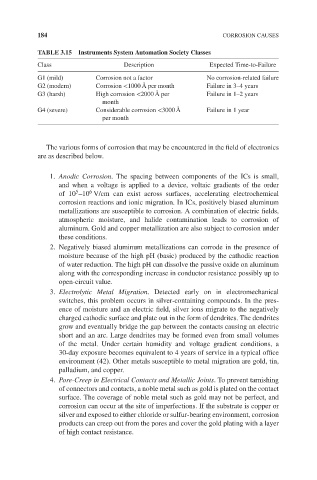

TABLE 3.15 Instruments System Automation Society Classes

Class Description Expected Time-to-Failure

G1 (mild) Corrosion not a factor No corrosion-related failure

G2 (modern) Corrosion <1000 Å per month Failure in 3–4 years

G3 (harsh) High corrosion <2000 Å per Failure in 1–2 years

month

G4 (severe) Considerable corrosion <3000 Å Failure in 1 year

per month

The various forms of corrosion that may be encountered in the field of electronics

are as described below.

1. Anodic Corrosion. The spacing between components of the ICs is small,

and when a voltage is applied to a device, voltaic gradients of the order

6

5

of 10 –10 V/cm can exist across surfaces, accelerating electrochemical

corrosion reactions and ionic migration. In ICs, positively biased aluminum

metallizations are susceptible to corrosion. A combination of electric fields,

atmospheric moisture, and halide contamination leads to corrosion of

aluminum. Gold and copper metallization are also subject to corrosion under

these conditions.

2. Negatively biased aluminum metallizations can corrode in the presence of

moisture because of the high pH (basic) produced by the cathodic reaction

of water reduction. The high pH can dissolve the passive oxide on aluminum

along with the corresponding increase in conductor resistance possibly up to

open-circuit value.

3. Electrolytic Metal Migration. Detected early on in electromechanical

switches, this problem occurs in silver-containing compounds. In the pres-

ence of moisture and an electric field, silver ions migrate to the negatively

charged cathodic surface and plate out in the form of dendrites. The dendrites

grow and eventually bridge the gap between the contacts causing an electric

short and an arc. Large dendrites may be formed even from small volumes

of the metal. Under certain humidity and voltage gradient conditions, a

30-day exposure becomes equivalent to 4 years of service in a typical office

environment (42). Other metals susceptible to metal migration are gold, tin,

palladium, and copper.

4. Pore-Creep in Electrical Contacts and Metallic Joints. To prevent tarnishing

of connectors and contacts, a noble metal such as gold is plated on the contact

surface. The coverage of noble metal such as gold may not be perfect, and

corrosion can occur at the site of imperfections. If the substrate is copper or

silver and exposed to either chloride or sulfur-bearing environment, corrosion

products can creep out from the pores and cover the gold plating with a layer

of high contact resistance.