Page 218 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 218

196 CORROSION CAUSES

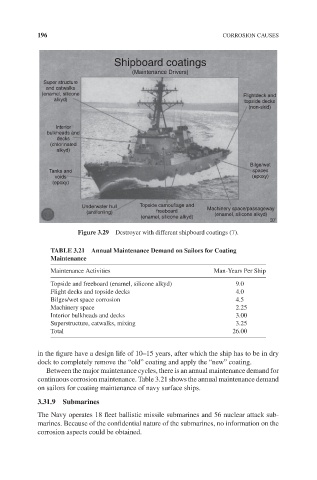

Shipboard coatings

(Maintenance Drivers)

Super structure

and catwalks

(enamel, silicone Flightdeck and

alkyd)

topside decks

(non-skid)

Interior

bulkheads and

decks

(chlorinated

alkyd)

Bilge/wet

Tanks and spaces

voids (epoxy)

(epoxy)

Underwater hull Topside camouflage and Machinery space/passageway

(antifonling) freeboard (enamel, silicone alkyd)

(enamel, silicone alkyd)

37

Figure 3.29 Destroyer with different shipboard coatings (7).

TABLE 3.21 Annual Maintenance Demand on Sailors for Coating

Maintenance

Maintenance Activities Man-Years Per Ship

Topside and freeboard (enamel, silicone alkyd) 9.0

Flight decks and topside decks 4.0

Bilges/wet space corrosion 4.5

Machinery space 2.25

Interior bulkheads and decks 3.00

Superstructure, catwalks, mixing 3.25

Total 26.00

in the figure have a design life of 10–15 years, after which the ship has to be in dry

dock to completely remove the “old” coating and apply the “new” coating.

Between the major maintenance cycles, there is an annual maintenance demand for

continuous corrosion maintenance. Table 3.21 shows the annual maintenance demand

on sailors for coating maintenance of navy surface ships.

3.31.9 Submarines

The Navy operates 18 fleet ballistic missile submarines and 56 nuclear attack sub-

marines. Because of the confidential nature of the submarines, no information on the

corrosion aspects could be obtained.